Autonomous inspection & monitoring software

Enterprise operations at scale, managed by one software.

Ready to scale your operations?

FAQs

Autonomous inspections and monitoring

What is artificial intelligence monitoring?

Artificial intelligence monitoring is the result of an AI-powered algorithm analyzing data on any process or operation. By using AI to analyze the data, the analysis is fully automated, generating insights on the process, asset, or operation being monitored.

Can inspections be automated?

Yes, inspections can and should be automated to boost safety and efficiency. Several sensors and technologies are used to automate inspections, and often robots and drones are used to automate visual inspections.

How does an automated inspection system work?

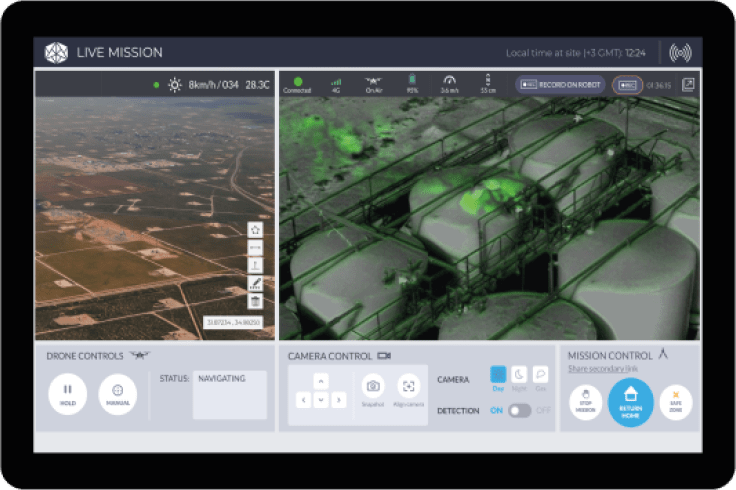

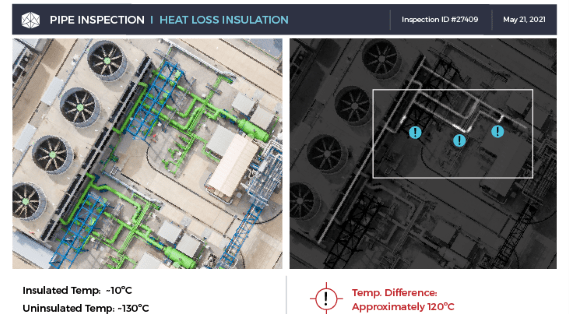

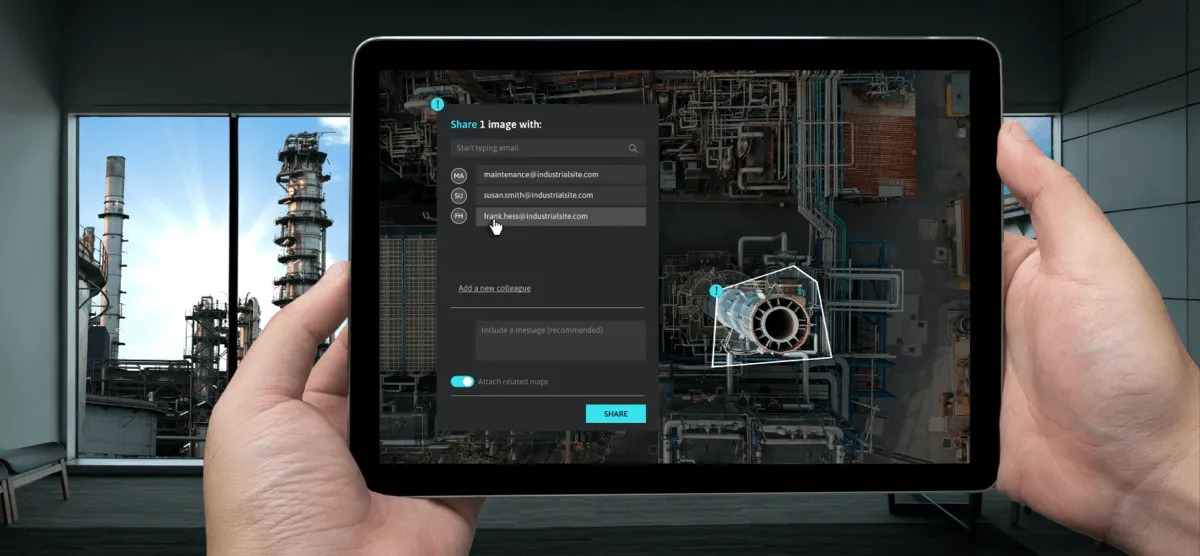

An automated inspection system automatically collects and analyzes data on any asset that needs inspection. An automated inspection system consists of the data collection platform (sensors, drones, robots, etc.) and the data management platform, responsible for requesting, managing, analyzing, reporting and distributing that data.

What are the advantages of automated inspection?

The top advantages of automating inspections are increasing safety and efficiency. Automated inspections are performed more frequently and are often higher-quality, and better equipped to catch faults before they turn into larger failures. They also significantly increase safety, reducing employee risk of performing hazardous inspections, and reducing facility overall risk by keeping assets in top shape.

What are different types of automated inspections?

There are many different types of automated inspections, often specific to the assets being inspected. Automated inspection types include laser inspections, pressure tests, flow tests. Every asset requires visual inspection to validate internal inspections and to inspect for external wear and tear.

What drones are used for inspections?

Many companies rely on both consumer and commercial drones to perform inspections, as a cost-effective and safe alternative to manual inspections. Drones useful for inspections include piloted drones, consumer drones, fixed wing drones, tethered drones, and fully autonomous drone-in-a-box solution.

What is AI in inspection?

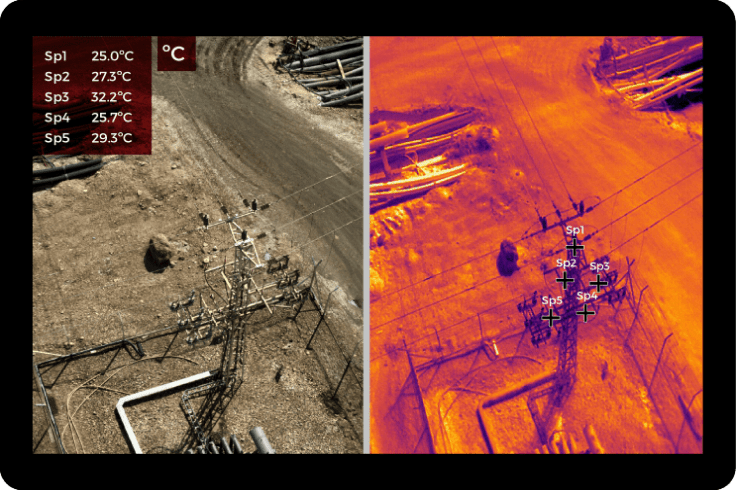

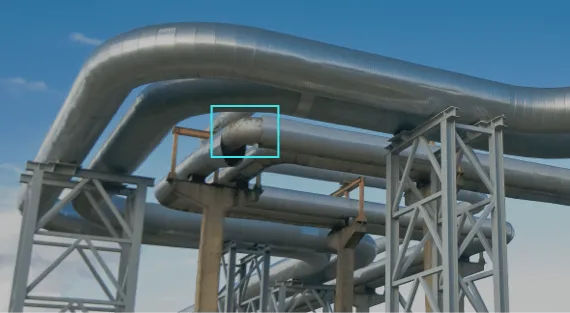

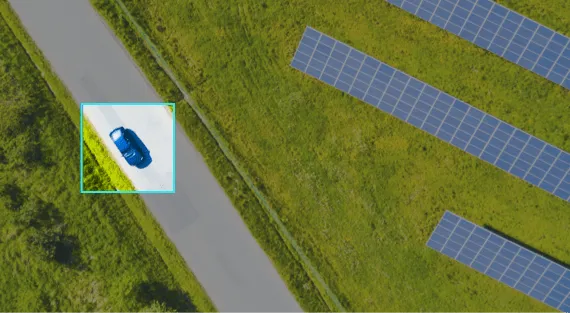

AI is used in inspection to automatically detect failures and anomalies, ignoring insignificant changes such as weather. The use of AI in inspections is a fairly new technology, and has the potential to greatly enhance inspection effectiveness and quality, reducing the cost incurred by 3rd party analysis services.

What is a vision inspection system?

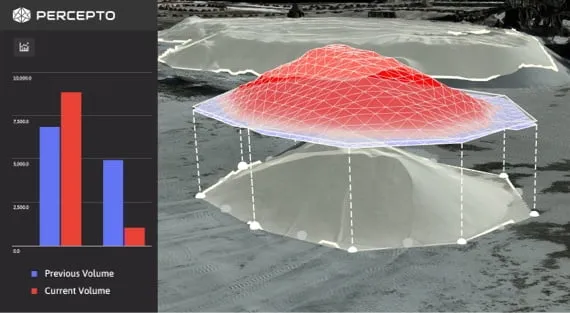

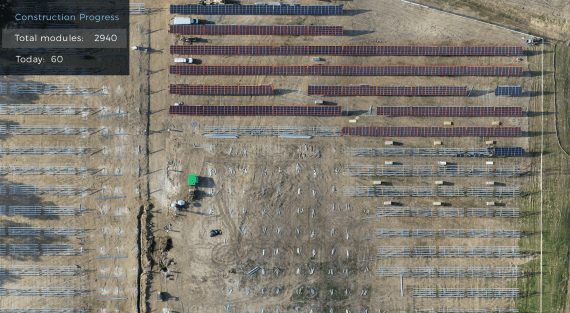

Vision inspection systems collect and analyze visual data on any asset, operation or process. Any visual data can be collected and analyzed, but typically drones or robots are used to collect data in vision inspection systems. Vision inspection systems inspect for anomalies such as structural damage, corrosion and leaks, as well as positive changes such as construction or pile inspections.

Can AI computer vision predict defects?

Some sophisticated algorithms can predict defects in assets, processes or operations. These algorithms rely on high quantities of repetitive visual data to detect faults and predict trends.

What are the current capabilities of automated visual inspection systems?

Automated visual inspection systems have many capabilities, including of course automating visual inspections. In addition, they are used to automate construction monitoring, pile inspections, security tasks, modeling and measurement and creating digital twins, emergency response and remote operations.