Remote operations: autonomous inspections and monitoring

Stay on top of your site, even when not on site

Remotely monitor any facility with on-site autonomous drones, Percepto AIM – and advanced regulatory approvals.

Restricted movement due to lockdowns has pushed industrial companies to reimagine operations and embrace the underlying technologies faster than ever. Remote operation are needed for daily inspections as well as critical situations, enabling business continuity, workforce safety, better situational awareness and organizational management.

Remote operations is the future here

Industry leaders have been benefiting from unmanned, off-site inspections for years

1. Software: Percepto AIM

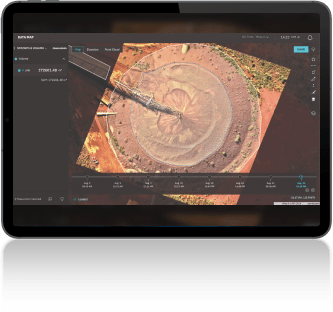

Autonomous robots managed by Percepto AIM from anywhere in the world, performing daily tasks in any weather condition, anytime. Robots perform risky inspections, security patrols, and emergency response, with any and all visual data collected on site aggregated and analyzed in one place. Critical and industrial facilities can prevent serious failures, respond quickly to disasters, and enable business continuity – remotely and without a human operator.

inspection

- Capture

- Upload

- Analyze

- Manage

3. Regulatory approvals

Operate autonomous drones remotely with advanced regulatory approvals, including BVLOS from day 1 in the US. Percepto’s drone regulation expertise enables industrial companies to benefit from autonomous drone operations without human involvement

Benefits of autonomous remote operations

Reduce operational costs

Autonomous inspections & monitoring without human intervention, and no 3rd party data analysis.

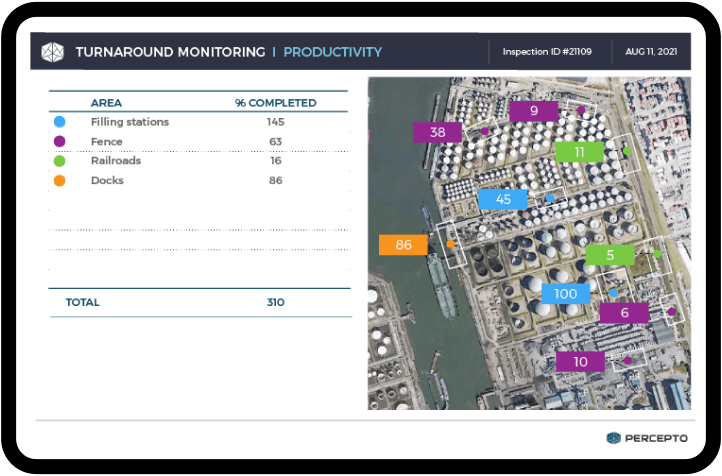

Effectively manage multiple facilities

Streamline operation and gain real-time operational insights into day-to-day operations, construction and turnarounds from anywhere in the world.

Enhance employee safety

Keep employees out of harm’s way during day-to-day operations and respond quickly and safely to emergencies.

Maintain business continuity

From pandemics, workforce shortages and inclement weather, maintain operations even when your team can’t get on site.

Efficient emergency response

Leverage safe and immediate response to emergency situations to gain enhanced situational awareness and respond efficiently to emergencies.

Autonomous inspections and monitoring via remote operations at:

- Electric utilities

- Oil & gas

- Industrial sites

- Solar energy

- Mining

- Ports & terminals

Autonomous inspections and monitoring via remote operations at:

- Electric utilities

- Oil & gas

- Industrial sites

- Solar energy

- Mining

- Ports & terminals

FAQs

Remote drone operations

What type of software is needed for remote drone operations at industrial sites?

A cloud-based solution that can manage on-site drones and robots. Cloud-based visual data management solutions can provide automated AI-powered insights which can be accessed from an operations center or any offsite location.

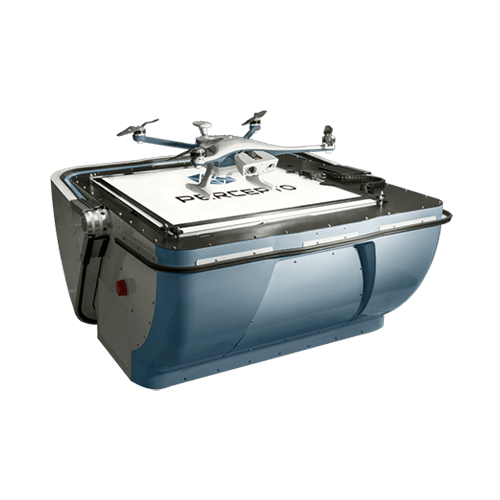

What hardware is needed in order to enable remote site inspections?

Remote site inspections are carried out by an autonomous drone or robot. The autonomous drone must be able to safely and automatically navigate its way according to pre-designed flight plans or ad-hoc, based on the situation at hand. In addition, it must be stored in a safe base which enables it to stay on the site 24/7/365 – protected from weather, charged and ready to launch, without the need for an operator on site.

Do I need approvals in order to conduct remote inspections with a drone?

Absolutely. Regulatory approvals are necessary to ensure safety in cases of drones flying over people, operating remotely or in extreme weather. BVLOS (Beyond Visual Line of Sight) can mean different things according to different regulatory bodies.

Learn more about complex drone operations.

What happens in the case of an emergency? And what if I need to take control of the drone?

Percepto Air drones are fully controlled by Percepto AIM software, which offers extensive remote operations capabilities. A mission can be launched ad-hoc in the case of an emergency event that calls for immediate attention, for example to inspect the aftermath of a flare-off or a hurricane storm. Percepto AIM also enables the option to to intervene in real-time, manually navigating the drone or aborting during the mission and bringing it to safe landing at the Percepto Base.

Brochure: remote operations

Learn how to empower your organization with remote operations. Automate preventive maintenance inspections, facility monitoring, emergency response and security – from any location around the world.