Autonomous inspection

Minimize industrial site shutdowns while meeting ESG goals

Autonomous inspections powered by AI detect changes, faults and emissions as soon as they happen.

Any facility can drive down costs, while improving worker safety and operational continuity – with autonomous robots performing frequent, high quality inspections. During construction, day-to-day operations and shutdowns or turnarounds, automating inspections are key for safe and efficient operations.

How automated inspections boost productivity and safety

Autonomous inspections at leading industrial facilities:

Top use cases at industrial facilities:

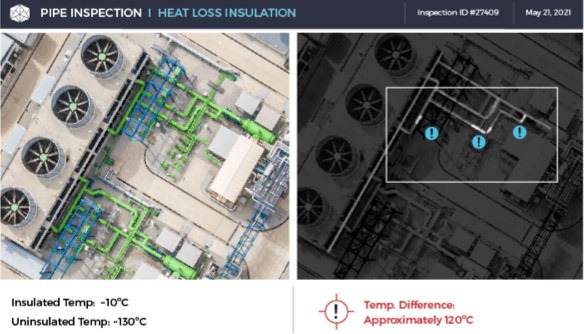

Pipe inspection

Pipe inspections with RGB and thermal cameras detect structural defects as well as insulation faults and environmental breeches.

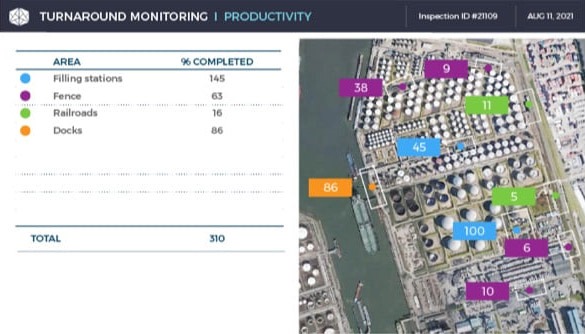

Turnaround monitoring

Monitoring actual turnaround progress and safety on a daily and hourly basis for accurate up-to-date monitoring.

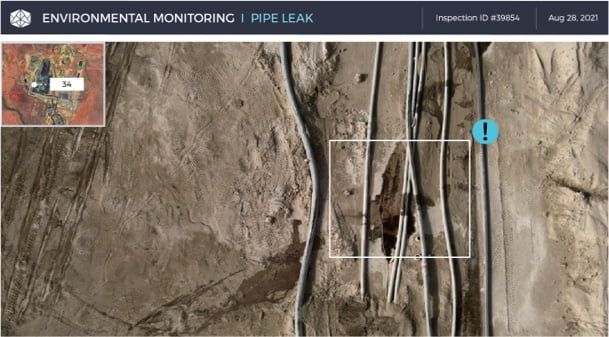

Environmental monitoring

The Air Max is the only drone-in-a-box with OGI camera, capable of detecting gas emissions.

Operations & maintenance

Regularly monitor for “housekeeping” tasks – and never miss an open hatch, equipment left out or other hazards.

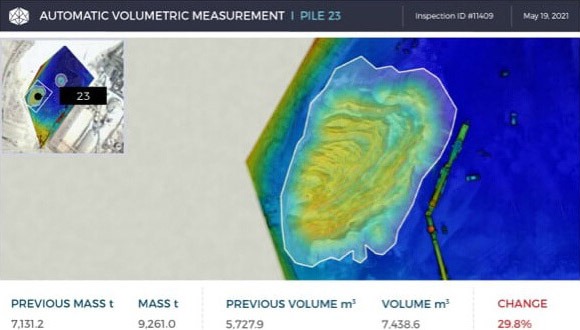

3D pile inspection

Conduct pre-scheduled automatic tank inspection missions scanning for environmental hazards, structural damage and other faults.

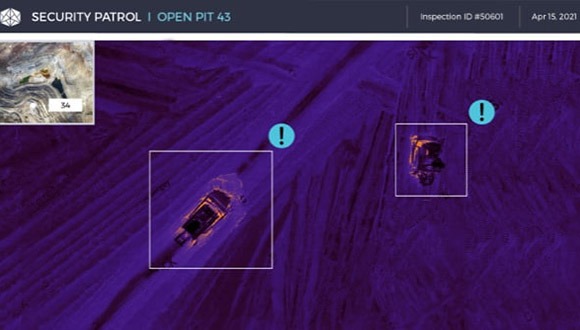

Emergency response and security

Autonomous robots act as first responders in the event of any emergency, and perform automated security patrols.

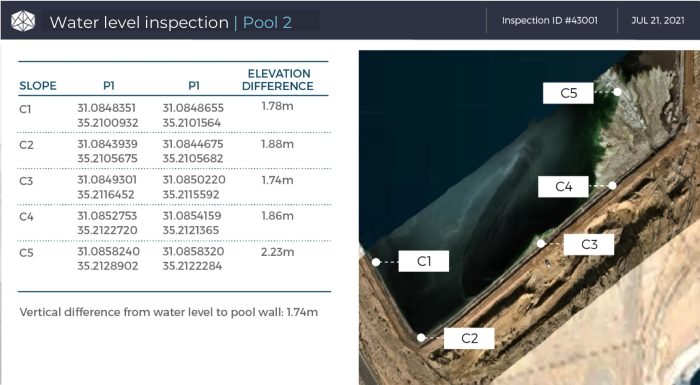

Water level inspection

Robots safely report on pool wall integrity, amount of solids in the pool, water levels, deposition patterns and more.

Explore the only end-to-end autonomous inspections and monitoring solution

Our Technology

Percepto’s solution for heavy industrial sites consists of autonomous robots managed by Percepto AIM deployed across a site, with a sophisticated cloud backend for AI-powered site inspections, monitoring, surveillance, and visual data collection & management.

Percepto enables industrial sites to:

Prevent downtime

Detect corrosion, leaks, poor insulation and more as soon as they happen – preventing faults from turning into shutdowns.

Streamline construction & turnarounds

Effectively meet deadlines and ensure safety with 24/7 autonomous monitoring and AI.

Go digital

Inspect and monitor your facilities from anywhere in the world, with autonomous drones and robots.

Increase safety

Detect spills, leaks & other hazards protecting your employees, the environment and the surrounding community.

FAQs

Autonomous inspections for heavy industrial sites

What is industrial site monitoring?

Industrial site monitoring is the process of measuring and recording parameters at a specific location in order to assess the status of an industrial plant or facility. This can be done manually, with human operators performing measurements and recording data, or automatically using sensors that are connected to computers and other devices.

Why are inspections necessary for industry sites?

The main purpose of this type of industrial inspections is to ensure that all aspects of the facility operate within safe limits and standards and to ensure efficient operations. Industrial site monitoring can also help to identify problems before they become serious enough to cause damage to the facility. It can also provide information about how well the facility is being managed, which can lead to cost savings by reducing downtime and increasing efficiency.

What are the benefits of automated industrial inspection and monitoring?

Site inspections can be conducted manually or automatically. Manual inspections require a person to physically visit each area of interest. This method is time consuming and expensive. Automated inspections use sensors to detect anomalies in the environment. These anomalies are then reported to operators who respond accordingly.

Automated inspections are typically used for large areas such as warehouses and factories. They have been found to be effective at detecting problems early on and reducing downtime.

What is industrial perimeter monitoring?

Industrial sites are often prone to theft, and require perimeter surveillance monitoring to detect intruders. Industrial perimeter monitoring can be done in a few ways:

- Manually, often in vehicle patrols

- With on-site security cameras or sensors

- With automated drones or robots

These methods are often combined to offer the greatest level of security.

Why are routine inspections so important to industrial sites?

By routinely inspecting industrial site assets, you can reduce risks and costs associated with unexpected events. Routine inspections help prevent costly repairs by identifying issues before they become major problems. If a problem is identified during an inspection, it may be possible to resolve the issue without incurring significant repair costs.

If a problem occurs after the fact, it will likely cost much more than if it was detected earlier.

How are industrial site inspections conducted?

Industrial site inspections are conducted in one or more of the following ways:

- Manually

- Using aerial photography

- Using ground-based inspections

- Using remotely operated vehicles (ROV)

During an industrial site inspection, site assets are monitored and inspected to ensure that they are operating within their design parameters. The purpose of this process is to identify potential problems before they cause damage to your property.

How automated inspections boost productivity and safety

To learn how leading heavy industrial sites fully automate inspections to minimize downtime and optimize production, get the e-book.