Industrial site visual inspection

Survey report

200 oil & gas and energy executives were surveyed worldwide to gain a deeper understanding of visual inspection drivers, practices, and trends.

Get the full report to learn about:

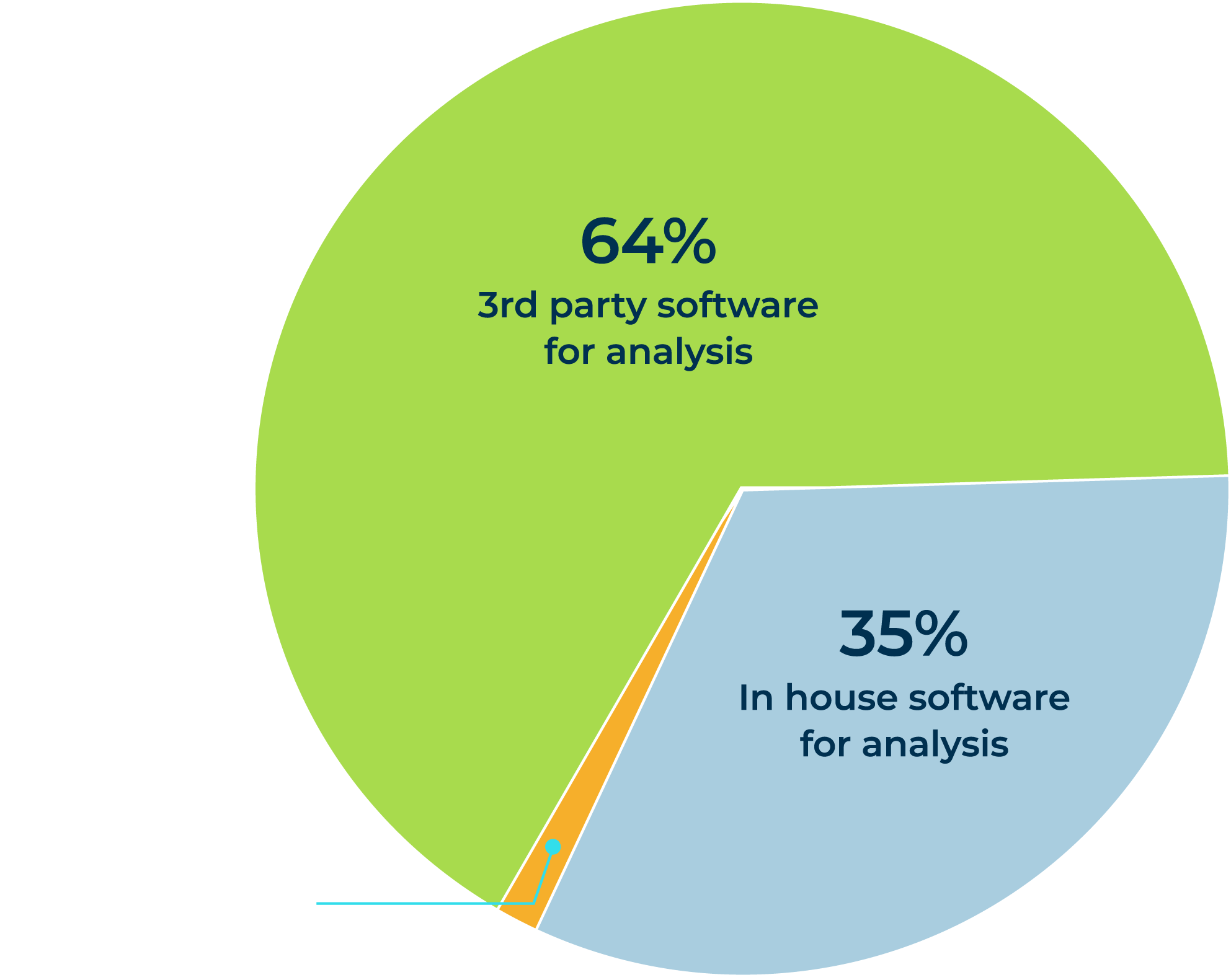

- Current technologies used for promoting asset integrity

- Inspection frequency and average number of inspectors per site

- Visual inspection digitalization and automation