How much does a major gas leak cost your facility?

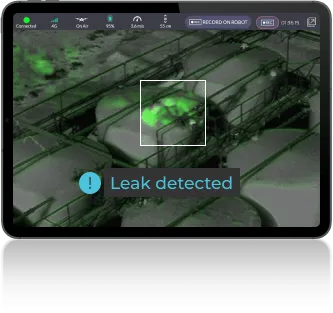

A US refinery saved $15M in one month with autonomous OGI inspections.

The detected leak prevented tank downtime; critical for minimizing product loss and boosting operational efficiency. With daily optical gas imaging (OGI) inspections, keep your employees safe and never miss a fugitive emission. All inspections routes and findings are automatically saved on the cloud for easy auditing and breadcrumbs.

Benefits of autonomous gas leak detection

Maximize productivity

Reduce product loss, minimize downtime and improve decision making with daily OGI inspections.

Streamline compliance

Automatically generate inspection audits including breadcrumbs. When leaks are detected, prove when the last inspection was and when repairs are performed.

Reduce OPEX

Increase inspection frequency and coverage while decreasing overhead.

Improve safety

Minimize employee exposure during manual inspections and automate emergency response.

Reduce carbon footprint

With daily, full-coverage OGI inspections, never miss a large leak again.

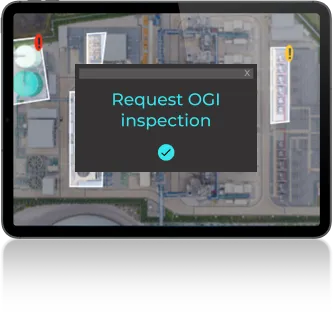

Easily detect emissions with Percepto AIM

Easily detect fugitive emissions with Percepto AIM. Select an asset you want to monitor or the insight you want to receive. That’s it. In the background, Percepto AIM automates the data collection, upload and analysis to get you the information you need.

- Capture

- Upload

- Analyze

Percepto Air Max OGI

The only drone-in-a-box with OGI payload, the Air Max OGI enables high-frequency, high-quality inspections – fully automated.

- Sierra Olympic Ventus OGI camera

- 16MP camera

FAQs

Automating gas leak detection

How does gas leak detection work?

Gas leaks can be detected by using a variety of methods, including manual inspection using sniffers or soap and bubbles, infrared thermography, acoustic emission (AE), ground penetrating radar (GPR), microwave imaging and of course Optical Gas Imaging (OGI).

How does optical gas imaging work?

Optical Gas Imaging is an effective tool in detecting fugitive emissions at an industrial site. The technique is used to detect leaks of hazardous gasses such as hydrogen sulfide, carbon monoxide and methane.

The principle behind optical gas imaging is that a light source illuminates the area being monitored and the resulting scattered radiation is detected by a detector. The intensity of the scattered radiation depends on the concentration of the target gas in the illuminated region.

There are two basic types of optical gas detection systems: those which use an array of detectors to measure the total energy of the scattered radiation, and those which employ a single detector for each pixel or cell of the image. In the latter case, the signal from the detector is integrated over time, typically using a charge-coupled device (CCD) or complementary metal oxide semiconductor (CMOS) sensor. This allows the system to operate continuously without requiring any mechanical scanning movements.

What are the advantages of OGI?

OGI has several advantages over other technologies. These include:

- It is non-contact – there is no need to physically touch the surface of the object being imaged.

- It is very fast – it takes less than one second to produce a full color picture of a room.

- It is highly accurate – it can detect concentrations of gasses down to parts per million.

- It is easy to install – it requires only a few hours’ training and installation.

- It is portable – it can be carried around easily and quickly.

- It provides real-time information about the leak.

Can thermal imaging detect gas leaks?

Using thermal imaging to detect gas leaks is a well-established technique. The principle of this method is based on the fact that heat transfer from a hot object (e.g., an engine) to its surroundings is reduced by the presence of gasses in the surrounding air, which leads to a temperature gradient between the hot and cold objects. This phenomenon can be used for detecting leaks in pipelines or other systems where there are two different temperatures at opposite directions.

The most common way of using thermal imaging to detect leaks is to use infrared cameras with long focal lengths. These cameras have a very high sensitivity and can easily detect small differences in temperature. However, they also have several disadvantages:

- They require a large amount of light to operate properly;

- Their resolution is limited to about 10 cm per pixel;

- They cannot distinguish between different gasses; and

- They are not suitable for monitoring large areas.

How does an OGI drone work?

Optical Gas Imaging drones work by:

- Detecting the presence of a gas leak, and then

- Determining its location on the property.

- Providing an alert regarding the detected leak.

- Notifying local authorities if required.

- Monitoring for leaks over time.

- Tracking the progress of repairs.

- Identifying the source of the leak.

Are Optical gas imaging Technologies effective for methane leak detection?

Yes, OGI sensors can detect an array of Volatile Organic Compounds including methane. They can also detect other gasses such as propane, benzine, butane and more.

E-book:

How to choose the OGI solution that's right for you

When choosing an OGI solution for your facility, you want to:

- Boost safety

- Meet ESG goals

- Meet regulatory standards

- Increase efficiency

- And more

Get the e-book to learn how to choose the best solution for your facility