Streamline PV site construction and operations

One software solution for solar construction and O&M

With growing demand for green energy, companies need to scale up, monitor multiple construction projects simultaneously and ensure deadlines are met. Guaranteeing construction quality, managing successful handover to operations, and optimizing maintenance and production prove a challenge.

Any PV farm can harness the power of automation to scale up solar construction and operations – with end-to-end drone inspections powered by Percepto Autonomous Inspection and Monitoring (AIM) software.

Solar PV inspection software

Top use cases for solar farms

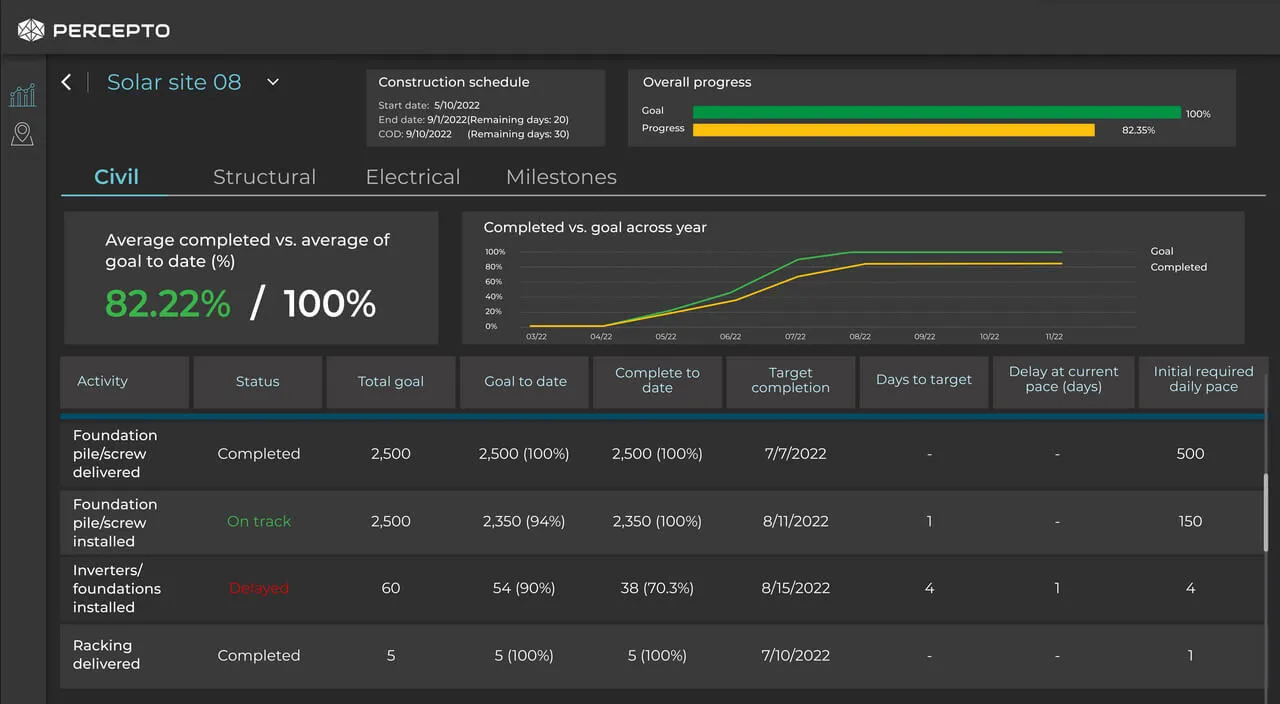

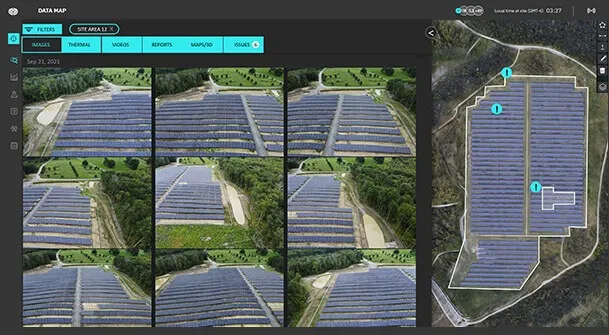

Monitor multiple construction projects

Monitor multiple contractors’ daily progress versus plan to prevent delays and overheads, all in one dashboard

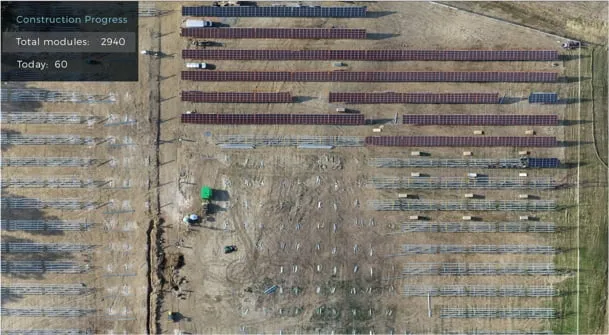

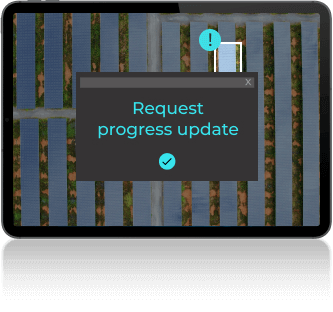

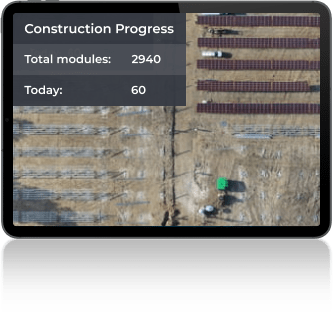

Track construction progress

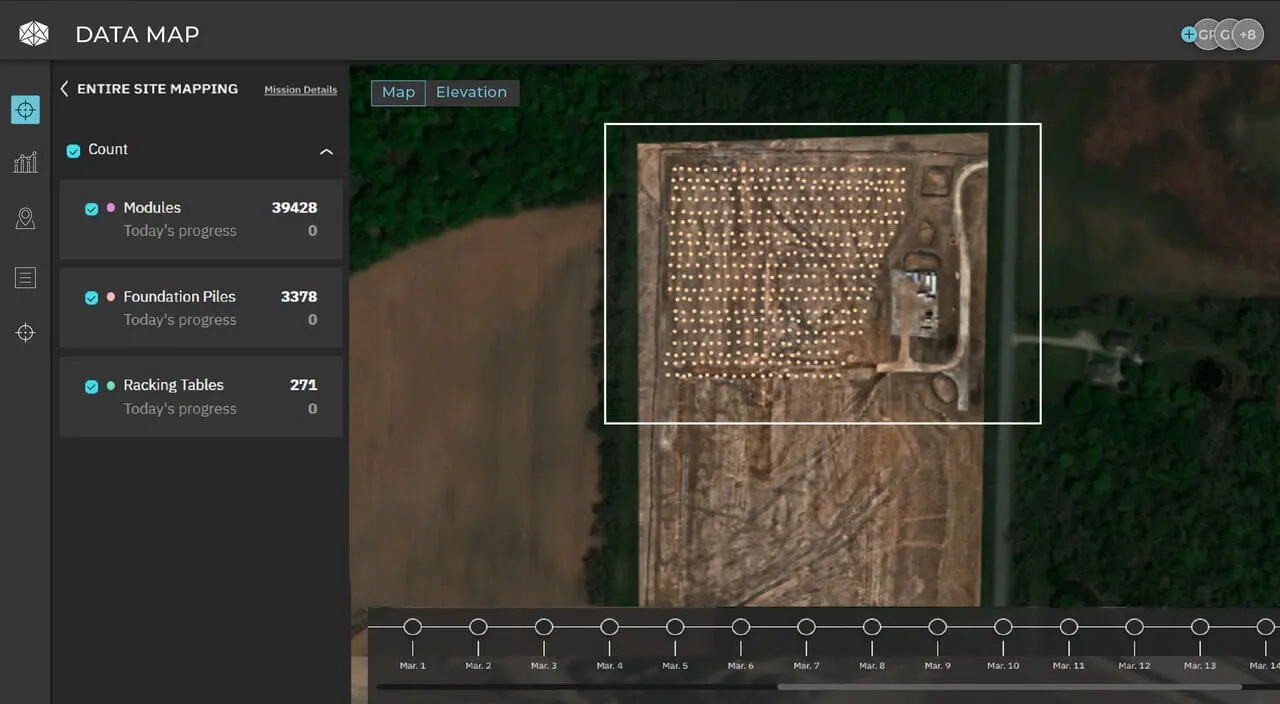

Ensure plans are on track with accurate object counting provided by advanced algorithms

Ensure compliance with plans

Compare as-built to plan on your site’s geospatial map using the CAD overlay feature

Enforce warranties

Automate your data management with records automatically uploaded to the cloud and stored on a geospatial data model

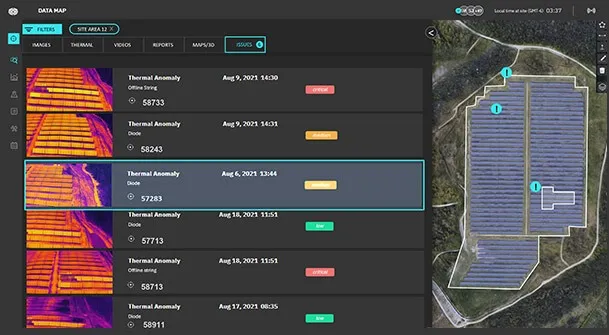

Streamline preventive maintenance

Direct your team to the right place at the right time, with insights you can’t get from the ground

Explore the only end-to-end autonomous inspections and monitoring solution

Percepto AIM cloud-based software solution

For asset owners, EPC contractors, and O&M providers

- Capture

- Upload

- Analyze

- Manage

Benefits of Percepto AIM for PV sites

Meet deadlines

Easily and accurately track construction timelines with daily progress reports

Stick to the plan

Detect deviations between as-built and design as soon as they

happen and avoid errors & rework

OpEx efficiency

Improve preventive maintenance by directing your team to the right place at the right time

Operate remotely

Get automated, on-demand, insights, and reports, for multiple sites, from anywhere in the world

Boost production

Never miss an offline string or tilted tracker, using frequent aerial thermal inspections, and PV anomaly reports

Enforce warranties

Streamline warranty claims with records automatically stored on a digital geospatial model

FAQs

Software solution for solar farms

How to inspect solar farms?

Industry best practices dictate that solar farms should be manually inspected once a year. Inspectors generally look for vegetation, hot spots and physical faults.

How do drone-based inspections improve preventive and corrective maintenance?

When your data analysis software automatically detects faults and issues such as tilted trackers or cracked modules, you can easily direct your team to the right spot at the right time and prevent small issues from becoming large ones. Give technicians detailed information about the problem so they will know exactly what equipment to bring and how to fix the problem in the shortest time possible.

How does a drone perform solar panel inspections?

Piloted drones are directed to solar panels, collecting visual data of the panels and other components. That data is later manually reviewed to look for faults or failures. Autonomous drones inspect solar panels at the same height and angle every time. Percepto’s autonomous drones feed highly repetitive and high-quality data to AI algorithms that detect faults and failures.

How exactly can frequent aerial inspections optimize production?

Drone based annual PV inspections are conducted by many solar farms in order to locate and record PV anomalies for warranty and insurance claims. As some solar farms settle for yearly basic thermographic analysis, others enjoy a more comprehensive solution; conducting frequent drone inspections and detecting thermal anomalies at the panel level, e.g. hotspots, along with visual faults, such as soiling or vegetation growing over panels, in a timely manner, that can hamper energy production.

How do you use all this visual data?

Drones can capture hundreds of images and videos, how can all this data be stored and managed? A cloud-based visual data management software can map all drone, robot, or sensor data on a user-friendly digital twin of your site. When scaling up, big energy companies choose to own their data from day one, keeping track of all construction projects in one place, recording every step of the way, to streamline decision-making and ensure everything runs smoothly.

How can drone inspections improve the construction of solar farms?

Frequent drone inspections enable remote site visibility, with insights you cannot get from the ground:

- Use drones for high resolution terrain mapping

- Accurately estimate groundwork based on aerial inspection

- Gain daily progress reports powered by drones

- Replace 3rd party updates with frequent, AI-powered progress reports

Does Percepto adhere to the IEC standard?

Yes! Percepto follows the global IEC standards for thermography PV inspections, ensuring high-quality, standardized, thermal data collection and analysis for our clients.

Solar PV inspection software

Learn more about the only PV inspection software for the entire solar lifecycle, from construction to commissioning and O&M. Meet growing green energy demands with automated, AI-powered software.