Autonomous inspection

Introduce remote operations to your mines, with autonomous drones and robots

Solve your facilities’ safety, availability and productivity challenges with remote inspections of piles, tailings dams and more.

With drones or robots automatically inspecting your mine, you don’t have to worry about risking employees – or missing faults – ever again. Gain automatic reports, 3D models and insights at the click of a button, from any location.

Automated inspections in mining

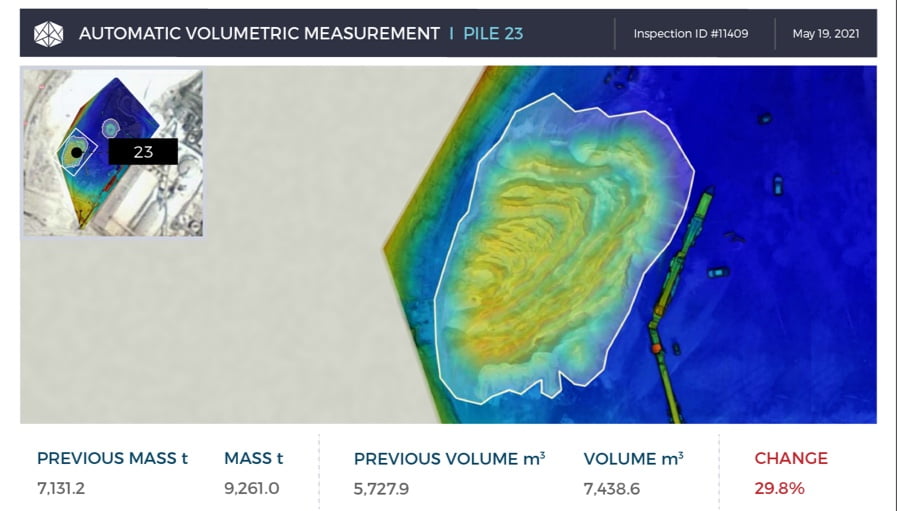

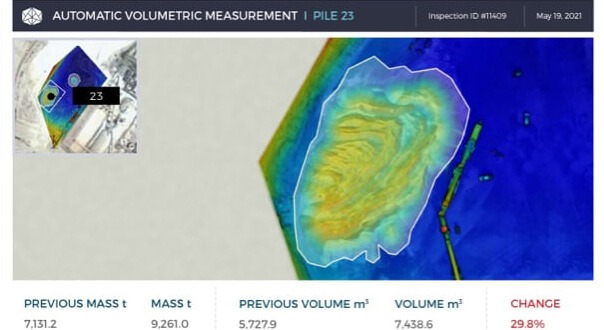

Spotlight on: 3D pile inspection

Ensure accurate, frequent pile inspections at your mine with Percepto AIM.

On-site drones perform regularly scheduled pile inspections, automatically generating volumetric measurements and 3D maps.

Top use cases at mines:

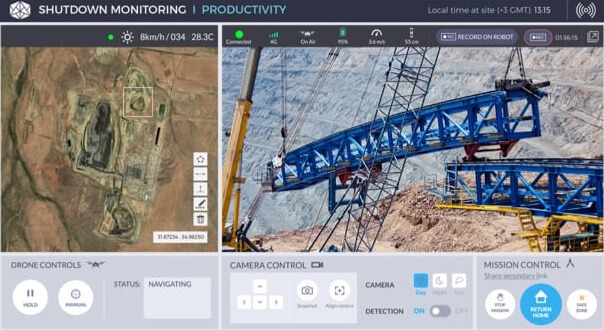

Shutdowns and project management

Ensure shutdowns and projects meet deadlines with objective, daily progress reports.

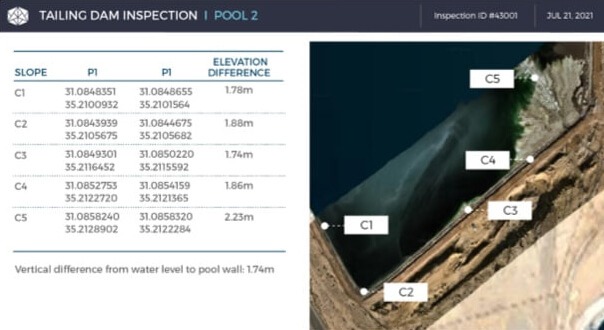

Tailings dam inspection

Robots safely report on tailings dam wall integrity, amount of solids in the dam, water levels in regards to the dam, deposition patterns and more.

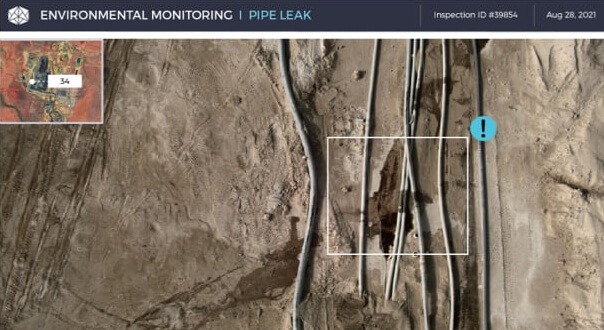

Environmental monitoring

Monitor tailings dams, leaks and wastewater, and keep your employees safe, without being exposed to hazardous elements.

Emergency response and security

Autonomous robots act as first responders in the event of any emergency, and perform automated security patrols.

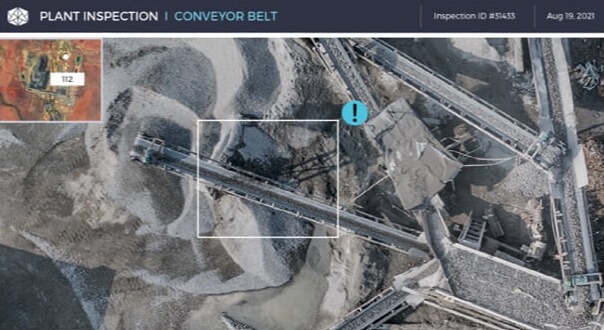

Plant inspection and monitoring

Monitor conveyor belts, detect corrosion, identify overheating, assess pipelines, monitor autonomous truck fleets and more.

3D pile inspection

Conduct pre-scheduled automatic tank inspection missions scanning for environmental hazards, structural damage and other faults.

Explore the only end-to-end autonomous

inspections and monitoring solution

Our Technology

Percepto’s solution for mining consists of autonomous robots managed by Percepto AIM deployed across a site, with a sophisticated cloud backend for AI-powered site inspections, monitoring, surveillance, and visual data collection & management.

Percepto enables mines to:

Increase safety

Autonomous robots perform risky inspections and detect failures early on, preventing potential accidents.

Go digital

Inspect and monitor your mining facilities from anywhere in the world, with autonomous drones and robots.

Ensure efficiency

With weekly or daily reports and 3D models, guarantee efficiency from better blast planning to efficient materials transport.

Reduce environmental footprint

Detect tailings dam failures, leaks and other hazards protecting your employees and the environment.

FAQs

Autonomous inspections

at mines

What is mining inspection?

Mining inspection is the process of inspecting a mine to:

- Monitor operations, to optimize operations such as materials transport planning

- Ensure that it meets mining standards and regulations, to prevent the occurrence of accidents. Mining inspectors are responsible for ensuring that mines comply

How are drones used in the mining industry?

The most popular use of drones in the mining industry is pile inspections. Leveraging their unique aerial view, drones provide an accurate and efficient method of monitoring stockpiles. Drones are also used to inspect other assets, such as tailings dams, and perform security patrols.

How are drones used for mining inspection?

Many mines rely on drones to perform inspections of critical assets such as piles, tailings, conveyors, pits, and more. Often a service provider arranges for a drone pilot to arrive on site to fly the drone, and send out the data to generate 3D models and other insights. Some companies operate the drones in house, and others rely on autonomous drones, which can be operated remotely, from an off-site remote operations center.

How can fully autonomous drones help improve mining?

Fully autonomous drones can help improve mining safety and efficiency. Because fully autonomous drones don’t require a pilot to perform inspections, mines can be operated completely remotely. Remote operations in mining are becoming increasingly desirable for safety concerns, remote locations of mines, covid-19, and efficiency. Remote operations also allow site managers and company executives to know what’s going on at their facility from any location.

What is UAV mining?

UAV (Unmanned Aerial Vehicle) mining is a new and emerging technology that allows for unmanned monitoring and inspections of mines. This uses unmanned aerial vehicles to efficiently and safely monitor mines during regular operations, shutdowns and in an emergency.

What is stockpile management in mining?

Stockpile management is the process of managing stockpiles of materials. It includes planning, monitoring and controlling stockpiles to meet production requirements.

The key elements of stockpile management are:

- Planning – Planning for future needs is essential. The plan should include information about current and expected demand, storage capacity, and available supplies.

- Monitoring – Stockpiles must be monitored regularly to determine if they are meeting production requirements.

- Controlling – When needed, stockpiles should be moved or destroyed according to established procedures.

How do you measure stockpiles with a drone?

There are two steps to measuring stockpiles with drones – data capture, and data analysis.

The first step to measure stockpiles with a drone is data capture. First, you need to fly your drone, capturing high-resolution images of the pile you’d like to measure. There are two ways to do this. One is to manually fly a drone over the stockpile, and the other is to rely on drone software to automatically operate the drone capturing the correct data.

Step two is analyzing the data. Data analytics tools will convert the images captured into an elevation map which will determine the volumetric measurement of the pile.

Autonomous inspections in mining: top 10 use cases

One of the biggest advantages of autonomous mine inspections is that employees aren’t required to be on site to inspect and monitor the mine. That means first and foremost that employees can perform their jobs safer and more efficiently.

By automating tasks including stockpile measurements, tailings dam inspections and environmental monitoring, any company can effectively increase safety and minimize downtime.