How to improve turnaround time at your facility

A heavy industrial plant was able to shorten its turnaround process by 2 days, yielding millions in savings. Can you?

Optimize the periodical turnaround maintenance and modernization process, so that your refinery, fertilizer, mining facility, petrochemical or power plant carries out the critical turnaround activities which will benefit the operation for the coming few years, while keeping timelines and costs under tight control. Harness robotics to make the unavoidable downtime as short as possible, and ensure an effective and orderly process.

Learn how Delek US better monitor and manage turnarounds

Benefits of autonomous turnaround management

Minimize downtime

Manage an effective process with enhanced situational awareness, damage assessment and recovery when needed.

Optimize workforce utilization

Reduce or even eliminate a diverse range of wasteful and mundane tasks via automation.

Enhance environmental monitoring

Daily monitoring, early detection of spills and leaks and contamination mapping.

Increase safety

Decrease employee exposure to risky environments; monitor clearance risk zones.

Reduce OPEX

Better control of contractors’ employees’ work and improved time management.

Boost equipment management

Ensure equipment availability and integrity: automated inventory, monitoring location of equipment, high-resolution aerial imagery.

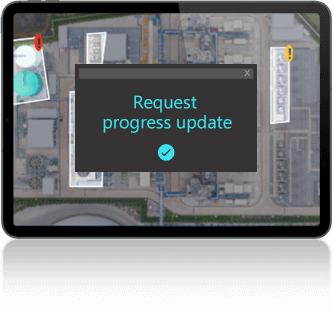

Percepto AIM: turnaround management software

Your hands are full already; you need to be able and focus on the most critical process or asset in the turnaround and get the insights you need. Percepto AIM will do the rest- automating data collection, uploading, analyzing and delivering actionable insights to you, wherever you are.

- Capture

- Upload

- Analyze

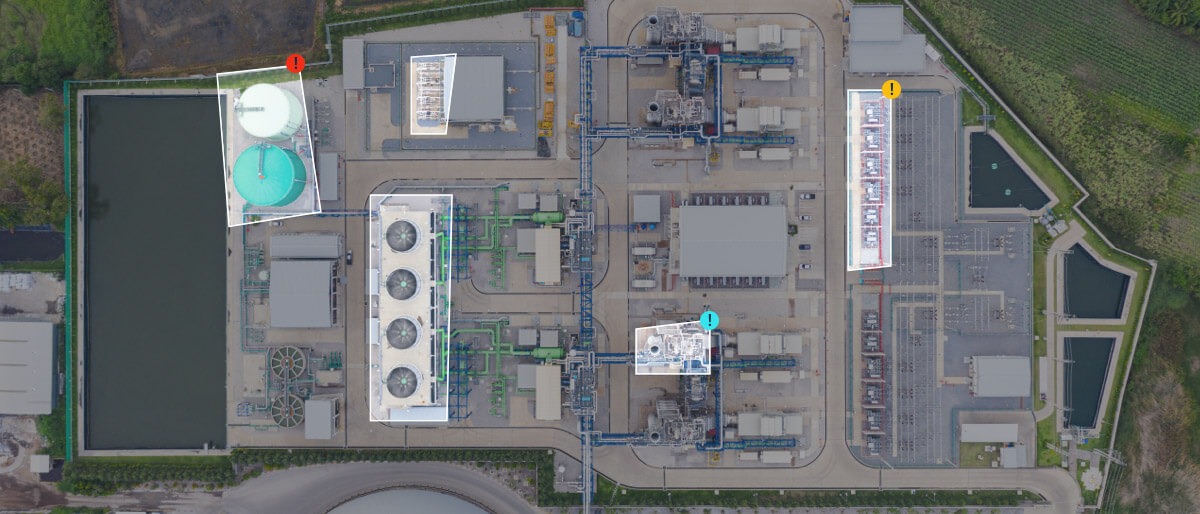

Tech highlight: object tracking

Stay updated of equipment status, monitoring movement of cranes, vehicles and other heavy equipment present on site based on previous information.

AI-powered technology delivers real-time actionable alerts, insights and reports.

Improve turnaround time at:

Electric utilities

Solar energy

Oil & gas

Mining

Industrial sites

Ports & terminals

FAQs

Automating turnaround monitoring

What is the purpose of turnaround time?

The purpose of a turnaround is to implement major technological advancements, upgrades and maintenance in order to optimize productivity for the coming years. Most industrial facilities schedule turnarounds, also known as planned shutdowns, on a regular basis, normally once in 3-5 years.

How do you manage a turnaround?

Managing a turnaround is a complex process, involving many different people with varying responsibilities and interests. A turnaround project may involve several departments within a company or even multiple companies, hiring of multiple subcontractors and specialized equipment. Turnarounds require a lot of planning, coordination, and communication as they need to be as effective and short as possible.

While industrial sites invest much time and asset in the planning of turnarounds, they often take longer than expected because of unexpected problems and the difficulty to oversee such a complex project in an effective manner.

What is turnaround maintenance?

One of the main goals of a turnaround is “radical” maintenance. Meaning, one that is above and beyond ongoing maintenance procedures taking place on a day-to-day basis. For example, the maintenance routine of a tank would entail regular checks that the fluids flow freely through the outlet pipe and nowhere else, that there are no leaks or rust, and the likes. During a turnaround the tank may be temporarily removed from service so that maintenance tasks can be performed, including emptying of the tank, scraping, assessing its performance- for example whether it’s time for a complete bottom replacement. All in order to ensure assets’ integrity and boost their productivity until the next scheduled turnaround.

What is a turnaround inspection?

A turnaround inspection is geared to support the objectives that have been defined in the scope of the specific turnaround. Turnaround inspections help stakeholders:

- Assess the maintenance status of specific assets on the site.

- Monitor a modernization project.

- Track progress of the process as a whole to minimize downtime.

A turnaround inspection is likely to entail more extensive planning and at times use of different equipment or robotics technologies. At the same time, just like any other inspection, it should maximize safety practices, minimize environmental hazards, and ensure compliance with regulatory standards.

How Delek US leverages AIM for better turnaround management

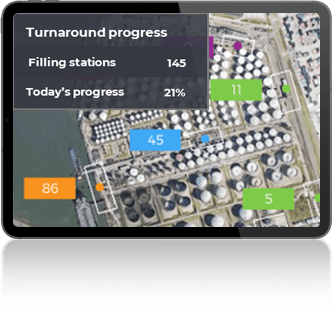

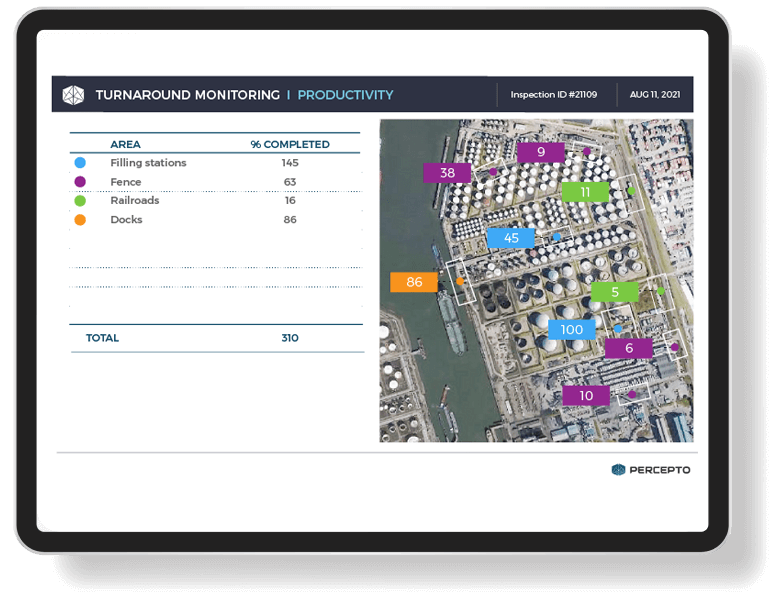

Delek US leverages daily autonomous turnaround updates to better manage and monitor their turnarounds

During one of their turnarounds, Percepto AIM delivered daily progress reports, leveraging drone data alongside visual data collected by other sensors and systems, such as fixed cameras. This helped with managing subcontractors, traffic flow, material movements, equipment availability, and personnel deployment, leading to fewer bottlenecks and increased productivity.