Drones for environmental monitoring

Automating inspection & monitoring is must to optimize sustainability

Maintaining infrastructure reliability and reducing emissions with frequent inspections are critical for meeting your ESG goals – why not automate both?

When large-scale failures occur within heavy industry, they not only make headlines, but cost millions in environmental and safety damages. Visual inspections are critical to ensure your site’s assets are in good condition AND to monitor for unwanted emissions and environmental infractions.

Brochure: Percepto Air drone-in-a-box

Benefits of automating environmental monitoring

Reduce emissions

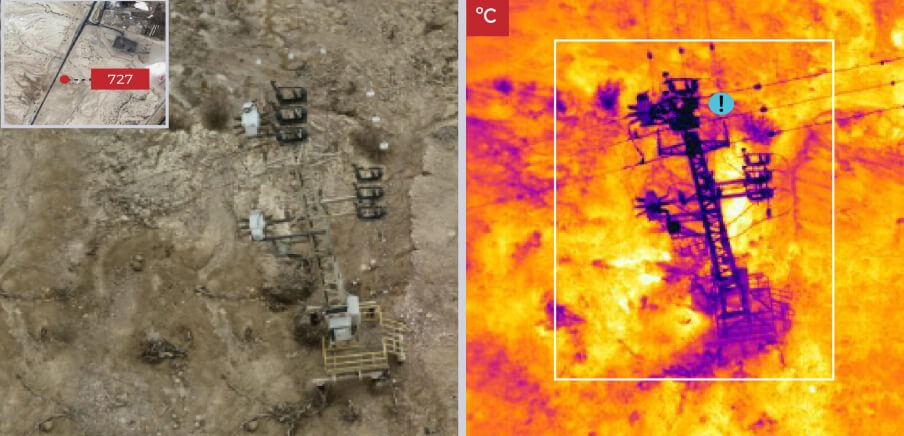

Run daily gas detection inspections with the only autonomous OGI drone on the market. Detect emissions as they happen, respond quickly and safely.

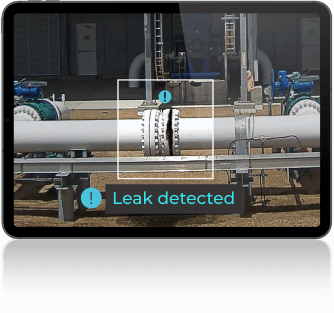

Minimize large-scale failures

Optimize preventive maintenance with automation – increase both inspection frequency and quality to detect failures early on.

Enhance site safety

Perform risky inspections and emergency response unmanned, keeping your employees out of harm’s way.

Easily prove compliance

AIM is your new cloud-based system of records, tracking automated inspections, any failures detected and infrastructure status post-repair.

Boost efficiency

Easily meet increasing regulatory standards for inspections with fully automated scans for leaks, temperature breaches, spills, pool integrity and more.

Remote operations

Inspect and monitor your facilities from anywhere in the world, with autonomous drones and robots.

Tech highlight: change detection

Percepto AIM delivers the only end-to-end change detection solution on the market for heavy industry.

It is the key to optimizing situational awareness, effective operations and maintenance as it serves as a flawless indicator of faults or defects.

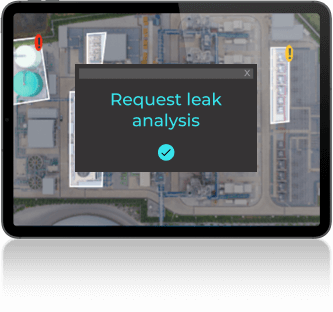

Easily automate inspections with Percepto AIM

Select an asset you want to monitor or the insight you want to receive. That’s it. In the background, Percepto AIM automates the data collection, upload and analysis to get you the information you need.

- Capture

- Upload

- Analyze

Percepto drone-in-a-box portfolio

The most advanced autonomous drones, equipped with RGB and thermal cameras, ASTM compliant parachute and integrated into AIM software solution

Percepto Air Max

The next-gen Sparrow designed for inspecting and mapping the most complex industrial environments, where highest-accuracy and durability are key.

Percepto Air Max OGI

Autonomous, end-to-end gas detection solution.

The only drone-in-a-box with an integrated OGI (Optical Gas Imaging) camera.

Automate environmental monitoring at your facility

Electric utilities

Solar energy

Oil & gas

Mining

Industrial sites

Ports & terminals

FAQs

Drones for environmental monitoring

How do drones help the environment?

For critical infrastructure, responsible for 40% of global carbon footprint, drones are critical tools to monitor asset health and emissions. Drones can be used in a wide range of other industries to help the environment, including forestry, agriculture, wildlife observation and more.

What is the future of drone technology in environmental management?

Drone technology will play a key role in global environmental efforts, as more and more stakeholders with significant carbon footprints turn to drones to help them reach their environmental goals. Recent innovations in drone technology such as drones with Optical Gas Imaging (OGI) payload, are becoming critical tools for Oil & Gas stakeholders to reduce their emissions.

How does critical infrastructure impact the environment?

Critical infrastructure ranges from energy, including Oil & Gas and power plants, to mining and waste management. Traditionally, these industries can contribute significantly to global carbon footprint if not properly monitored and maintained. Critical infrastructure failures such such as power grid fires and tailings spills can have widespread impacts, causing forest fires or wildlife destruction for example. For stakeholders responsible for maintaining critical infrastructure, keeping their assets (i.e. transmission lines, pipes, tanks and tailings) in top condition can help prevent large scale failures.