There’s a lot of talk about “end-to-end” drone solutions, but less about what that actually looks like. This blog explores what “end-to-end” means in the context of drone inspection, including data collection, analysis and management. What are the parts that make up the whole? (Hint – it’s about a lot more than just drone data collection.) And how does it affect the value you get from your drone solution?

Many solutions available today do a great job handling specific steps in the drone inspection and monitoring workflow, but do not provide a comprehensive solution. For example, some drone solutions focus only on drone data collection, i.e. planning flight routes, launching the drone, flying the mission, and uploading the visual data. Then, the facility or a third-party service provider handles drone data processing and analytics to detect any issues that should be attended to.

A drone solution that doesn’t include data analytics for example, isn’t an end-to-end solution. A data management solution that doesn’t automate the drone data upload is also not an end-to-end solution.

With extra manual steps or multiple solutions in play to automate inspections, enterprises are not getting what they really need: accurate and frequent insight delivery from one easy-to-use solution. This has been made clear by the spate of closures, acquisitions, and pivots over the past year or so among companies that took the focused approach. Missing the value of a complete solution, the market is voting with its feet.

Real value is gained with a fully autonomous end-to-end solution, or a “drone-to-report” solution. Consider the evidence: when ALL steps are part of a single, unified and unmanned solution, inspections are more frequent, efficient and higher quality – and more faults are caught before they become larger failures.

Why an end-to-end solution is critical for inspections

Critically, a fully autonomous, end-to-end solution improves safety by reducing overall risk to the facility by keeping assets in top shape.

- It allows for a much higher frequency of inspection, thus detecting issues before they become problems

- It increases employee safety, by removing employees from at risk inspections and emergency downtime events

- It collects data routinely, delivering more quality data and higher quality, actionable insights

From drone data collection to insight delivery: what’s involved?

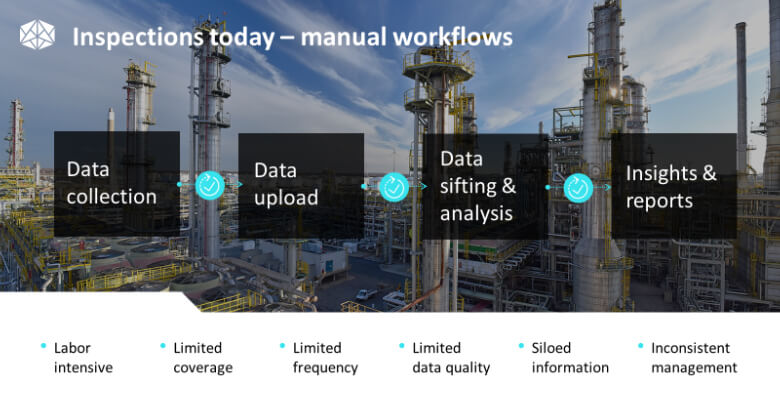

The drone inspection workflow comprises multiple parts. Each of which may involve several manual (not end-to-end) touchpoints, depending on the type of drone solution.

Drone data collection and upload

Many solutions require a trained pilot to physically move the drone to the take-off location, collect the drone after landing, remove the battery and charge it for the next flight. Due to the need for significant manual intervention and logistics involved, visual inspections are typically conducted less frequently than they should be.

And even when they are conducted, the pilot needs to manually upload the data at the end of each flight – adding an extra manual step. A bigger issue is that data may be uploaded and stored in different ways by different people. The data may also be siloed in different platforms, which may not be accessible to all the relevant stakeholders, and some people may lack training on how to use the different software s

A drone-in-a-box eliminates those manual steps and labor costs.

When a drone-in-a-box (an end-to-end drone data collection solution) is launched, it performs missions and returns to its “box” – without any human intervention. Moreover, the drones automatically upload data to the cloud at the end of each flight.

Drone data sifting and management

The next aspect of an end-to-end solution to consider is what happens to the data once it has been uploaded. Is it tagged, sorted and analyzed against past data? How this process is managed can make a huge difference. Is the data saved on the cloud and shared with the team, or is it saved on an individual’s desktop, perhaps siloed in different departments? Who has access to the data? Who analyzes it, and how long does it take?

If visual data management is done manually, the task can be onerous. Imagine sifting through many tens or hundreds of images and video files to understand which images need to be looked at closely, then looking for the relevant images from previous inspections for comparison. What happens when different people handle these tasks, classifying and organizing images in different ways? Rather than a needle in a haystack, it’s like having dozens of haystacks, each with multiple needles with subtle but critical differences. How do you find the one (or several) that you’re looking for?

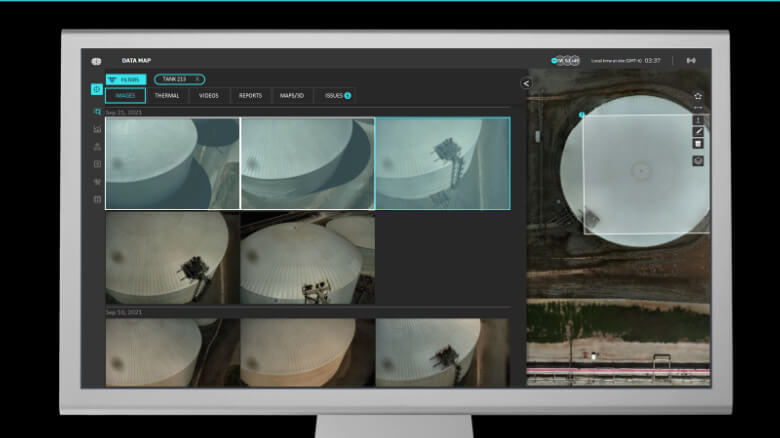

Further complicating the situation, most systems store and tag data by date or drone flight number, making it difficult to find images unless it’s known when they were taken. Contrast this with a site-centric approach: tagging data by asset category, name, and other parameters that enable easy searching and comparison.

Managing drone data is automated in an end-to-end solution. It’s automatically sorted by asset and data type. So when a user wants to find information about a specific tank for example, they can easily see all RGB images, thermal images, videos, reports and issues.

With automated, asset-centric drone data management, visual data is tagged according to the asset, instead of by simply flight number or time

Drone data processing and analysis

The key to an end-to-end drone solution for inspection is automatic, AI-powered data analysis. With powerful and advanced AI, no faults go unnoticed, so employees can depend on the solution to perform accurate inspections.

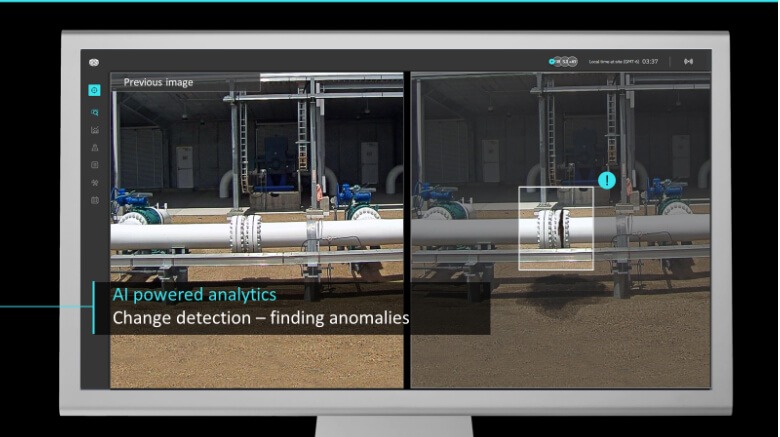

Comparison to historical data is fundamental for drone data analysis to support a successful reliability program. To identify faults, the most recent images of each asset must be compared to previous images – but not just any image. For a solution to be able to detect a leak, it can’t compare an image taken now to an image taken say 30 minutes ago. Both images will show a leak, and no change will be noticed. So the solution needs to be able to sort through historical (days, weeks, months) data and choose the “right” image to compare to.

If we think about that happening manually, we return to the ‘needle in the haystack’ big data challenges. Sifting through multiple images of each asset taken from different angles, for numerous assets on site is overwhelming in magnitude. There’s simply too much data for it to be analyzed manually.

Some companies have automated their drone data analytics, using UAV data processing software or a service provider. Depending on the platform or provider, results may take several hours or days. Delayed results lead to a longer time-lapse when issues are not attended to, allowing them time to worsen and become more costly to repair.

Another limitation of a third-party platform or service is they may not be able to integrate data from external sources like ground robots, fixed sensors, and other devices.

With an end-to-end drone solution, all visual data and analytics are handled automatically. The automatic analysis integrates both ongoing and historical data to accurately detect anomalies and identify trends. And results are available in real-time – no delays, no gaps, and no searching for that proverbial needle.

End-to-end drones with AI powered analytics detected a leak comparing to a previous image of the same pipe

Reporting and sharing

The way insights are distributed to stakeholders and decision makers is often overlooked. Third-party analytics software may provide the details you need, but who receives the insights? Where does it get saved? How long does it take for the data to get into the right hands for action to be taken?

With an end-to-end solution, or “drone-to-report” solution, the right information gets into the hands of the right people quickly. Real-time alerts for critical issues are automatically sent to relevant stakeholders. Scheduled, AI-driven reports on anomalies, trends, 3D models, measurements and more, are automatically generated according to your defined schedule and delivered to whomever is subscribed to each report.

The end-to-end value of an end-to-end solution

With a single end-to-end drone solution, inspections occur more frequently, are more effective and of a higher quality.,Stakeholders can focus on their sites rather than concern themselves about visual data management.

In a nutshell: when looking for a drone solution that will bring the maximum value to your enterprise, it’s vital to look at the big picture. Avoid solutions that automate or simplify only part of the inspection process and choose a complete solution that automates everything from data collection to data processing and analysis.

When it comes to automated inspection, the value of an end-to-end solution really does equal more than the sum of its parts.