Whether it’s power grids or communication lines, the public counts on critical infrastructure to be up and running consistently. Like an umpire’s call at a sporting contest, people may not notice when critical infrastructure works as it is designed, but when it fails, the results are glaring. Look at the massive system failure in Texas which led to lives lost and cost billions of dollars.

Because of the serious repercussions that are felt when industry giants’ infrastructure suffers outages, it’s imperative that companies do everything possible to ensure things are running smoothly.

The best way to prevent outages is by inspecting critical infrastructure frequently and accurately. Around the world, industry giants are automating inspections to do just that. Relying on autonomous drones and robots allows companies to monitor their facilities and fully automate day to day site inspections, as well as respond to emergencies.

Check out how some industry giants are benefitting from automated inspections and read the e-book for all the details.

Florida Power & Light responds swiftly to hurricanes with autonomous drones

Despite inspections and the best of intentions, sometimes problems arise that can’t be foreseen.

Stormy weather is one such problem. The South Florida Sun Sentinel reports that 2020 was a “record-breaking season, which generated 30 storms, including 13 hurricanes, subjecting the United States to 12 direct hits.” They report that AccuWeather is predicting 2021 will be another rough season of seven to 10 hurricanes. Several of these are expected to reach major hurricane strength, with winds of at least 111 mph.

Past storms such as Hurricane Irma and Dorian wreaked havoc on power lines in Florida.

Florida Power & Light Company (FPL), which serves 10 million plus people across the state, has taken a few steps as they strive to make their service more reliable and responsive. One such step is to utilize drones to automate inspections, which allows them to easily monitor hard-to-reach places and inspect critical infrastructure.

The autonomous drones can also be quickly deployed after a hurricane, with an on-site enclosure that can withstand hurricane 5 level winds. After a storm, the drones are dispatched immediately to scan power lines, providing a unique aerial view, and safely guiding maintenance crews to downed lines. This helps FPL to speed up restoration after a storm, as they can more efficiently direct crews and equipment to locales where they are most needed.

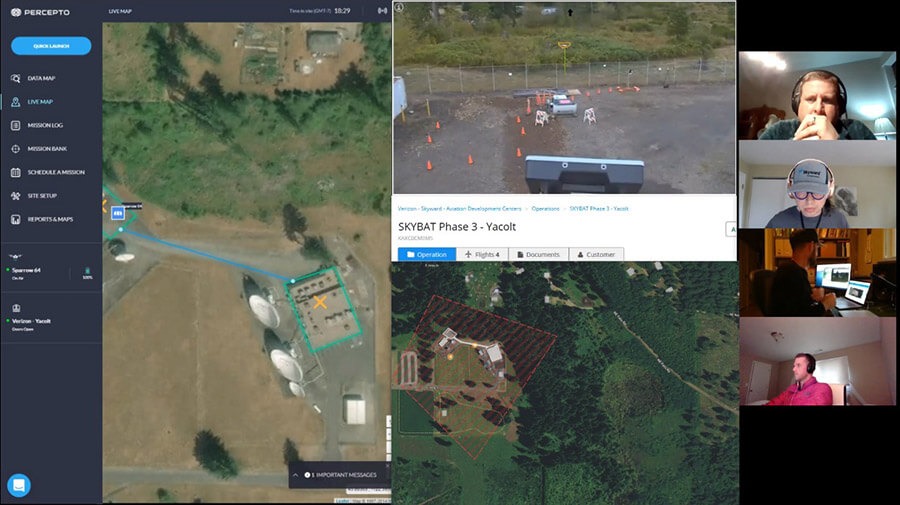

Verizon minimizes outage downtime with autonomous drones

A world leader in providing technology and communications, Verizon relies on autonomous drones to inspect their telecommunication lines in the event of an emergency. In a press release, the chief strategy officer of the company, Rima Qureshi, said “Innovations in airborne technology have enhanced our ability to inspect our sites without putting engineers in harm’s way, and provide our first responders with reliable communications.”

When the West Coast wildfires occurred, Verizon sent in drones from miles away to inspect their infrastructure, keeping their teams safe and quickly identifying critical areas requiring repairs.

Autonomous drones and robots help industry giants protect critical infrastructure. And when issues and emergencies arise, drones and robots can help minimize the damage.

Preventing outages with frequent, high quality inspections

Automated inspections, as opposed to manual inspections, are simple. Using autonomous drones and robots removes safety concerns associated with power grid inspections for example. Also, no personnel are pulled from other responsibilities. Finally, automated inspections rounds can be performed more efficiently than manual inspections and are more accurate.

Because of the multiple benefits and ease of automated inspections, industry giants can inspect their infrastructure at much higher frequencies. Regularly inspecting infrastructure helps prevent outages, since issues can be detected as soon as they happen, before they become significant.

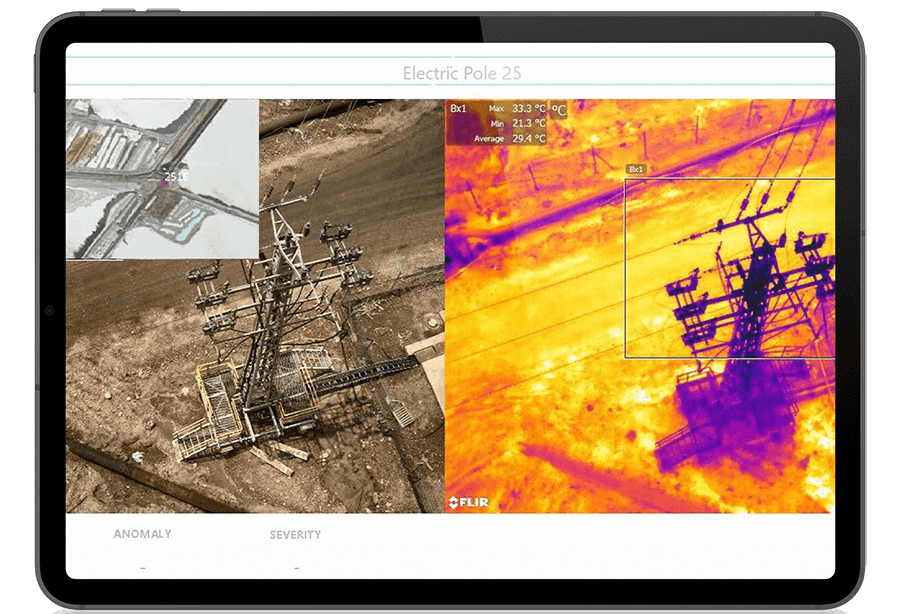

Israel Chemicals Ltd. (ICL) Dead Sea, a major chemical manufacturing facility, runs their own private electric grid. They use drones to provide aerial thermal imagery of power grids to prevent outages.

The climate where the company is located can reach extreme temperatures – up to 121°F in the summer. This is just one of the challenges the global specialty minerals and chemicals company faces when it comes to performing manual inspections. Others include the massive size of the plant and the complexity of their mission critical infrastructure.

In light of these factors, ICL Dead Sea was determined to increase inspections to prevent shutdowns or downtime at the facility. Keeping down the time and costs of doing these inspections, however, was essential.

ICL Dead Sea fully automated their routine site inspection with autonomous drones. Since automating inspections, ICL Dead Sea does not think twice about performing an inspection, and they have seen an increase in inspection accuracy.

When inspections detect a problem such as leaks and abnormal temperatures, maintenance teams are notified, allowing them to resolve the problem before it escalates. In the past when manual inspections were performed, staff was typically responding to failures in real time, which already had led to outages.

Frequent automated inspections with drones and robots add a significant layer of protection and help companies both prevent and deal with emergencies.