Thermal imaging is not what I’d call ‘the new kid on the block’. After all, cameras that capture infrared images and allow temperatures to be read from the pixels have been around for a while. What has changed first and foremost, is the way thermal data is collected. More and more organizations are relying on drones to collect thermal data that can be used to monitor their infrastructure while looking for overheating components, thinning insulation, and more. As a result, the quantity of thermal data collected has increased significantly. Now the question is how to effectively review and analyze all that data. Clearly, thermal data management and analysis software needs to become more sophisticated to keep up.

With the right tools for thermal imaging, you can visualize energy losses, identify problematic wiring, and so much more. All these issues are critical when it comes to increasing our infrastructure’s reliability and reducing its downtime. In this blog, I’ll explain how Percepto AIM’s thermal image analysis software has transformed the way we manage and analyze thermal data collected by our drones.

Thermal image analysis before and after Percepto AIM

Before we started using Percepto AIM to manage and analyze our visual data, it was a challenge to ensure reliability and minimize downtime. Our drone operators would collect a lot of data, and then our team would have to upload it, sift through it, and use 3rd party software to analyze it. With so many steps, some of the data never got analyzed. AIM changed everything.

- Cloud-based software: Before AIM, data captured was analyzed in on-premise software that required individual licenses. This significantly limited who had access to the analyzed data, especially with IT and security protocols in place. Simply put, having a cloud-based software makes it easy for anyone to use thermal tools and get the insights they need to do their job properly.

- One central repository for all data: We were using multiple softwares to analyze our data. For example, you can’t analyze data captured by DJI drones on FLIR’s platform. Now, all our data – whether from Percepto drones, DJI, or FLIR—is in one place. And it doesn’t need to be moved to other locations or tools for analysis, which is a big time saver. More critically, it provides a holistic picture of our infrastructure, as all the data is managed side by side.

- Advanced AI-powered analytics: Then, it was a matter of analyzing the data and making a report. To be honest, when we were manually analyzing data – a good chunk of it wasn’t being analyzed. Especially when it involved a power grid, which has TONS of data. Now, we can use Percepto AIM to analyze the data and have AIM automatically generate reports. The real game changer for us is Percepto AIM’s anomaly detection. The advanced algorithm compares the most recent thermal data collected to previous data, and detects any temperature differentials we define as critical.

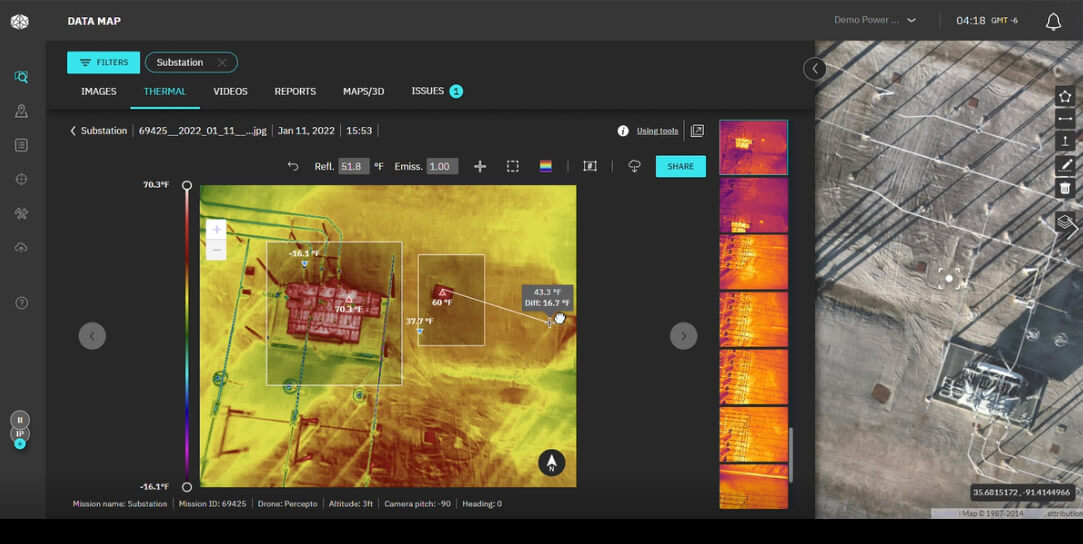

- Intuitive software: Before, we had to slog through the data and manually tag any problem with the asset where it was found. Now, all that data is automatically uploaded and geotagged on a geospatial map of our site. AIM software makes it easy to find what you’re looking for, see how it’s changed over time by comparing it to past inspections, or get detailed information on exactly where and how severe the problem is.

Let’s take a closer look at the software itself.

Why you need an advanced thermal image analysis software

It wasn’t enough for me just to have thermal tools that solve data bottlenecks for my organization. They had to be advanced tools that would help us identify temperature changes so we could prevent outages. With AIM, it was clear we were getting high-quality thermal analysis, empowering us with the temperature-based insights we needed to boost reliability and reduce downtime.

To give you a taste, here are just a few of the advanced features you get with Percepto AIM:

Automated analytics – Percepto AIM software offers advanced data analytics by using machine learning algorithms to analyze large amounts of thermal data collected. It’s an end-to-end solution that provides real-time data visualization and actionable insights, enabling us to make data-driven decisions and improve operational efficiency. For example, AIM saves us huge amounts of time by generating reports and identifying anomalies like hot spots or detecting extreme temperatures on electrical equipment. Now, we can initiate proactive maintenance on things like loose connections, faulty components, or insulations issues–before they cause serious damage or outages.

Thermal tools – If you want to analyze the data further for yourself, Percepto AIM offers a wide range of thermal tools. Here are some highlights:

- Color palette: Select the palette you want to use for the displayed image, whether inferno, white hot, black hot, artic or other variations.

- Temperature range: Annotated measurements let you select the temperature range to display.

- Spot measurement: Place a pin in any spot on the image to see and label its temperature.

- Box measurement and comparison: Create a box and have AIM automatically calculate and display the differential for the lowest and highest temperatures, or compare it to the temperature for a spot outside the box.

- Emissivity and reflected temp: Set the reflected temperature and emissivity level to accurately represent temperatures based on the properties of materials.

- Annotate and share: Mark any issues directly on the image, then share with any stakeholder in your organization.

Ensuring infrastructure reliability

Percepto AIM’s unmatched data management and thermal image analysis software offers a powerful solution for enhancing preventive maintenance and ensuring the reliability of any infrastructure. By automating insight and report generation, AIM enables organizations to identify faults at their earliest stages – before they escalate into large-scale failures.

With Percepto AIM, organizations across sectors such as energy, mining and storage and processing are minimizing the occurrence of large-scale failures. It’s saving them millions, and preventing serious safety and environmental implications. And of course, by keeping their assets in top shape, companies can better guarantee the critical infrastructure reliability their customers depend on.

Percepto AIM is a must-have software solution – for thermal image analysis and more

Percepto AIM has changed the way my organization deals with thermal data, enabling improved data workflows AND high quality analytics. The new, more efficient processes give us actionable insights that translate directly into optimized preventative maintenance, improved reliability and heightened safety.

With the simplified inspection and monitoring process, we’re also benefiting from enhanced environmental monitoring, increased productivity and unparalleled efficiency. Percepto AIM is a multi-mission solution. We came for the thermal image analysis tools, and gained the bonus of anomaly detection, volumetric measurements, advanced data management, and much more.

Ask for a demo to see how Percepto AIM can reshape your organization’s visual and thermal inspections!