Insights from Percepto’s market survey

A series of high-profile methane leaks at sites around the world, such at Aliso Canyon, California and Nord Stream in the Baltic Sea, have brought the oil and gas industry under increasing scrutiny in the past decade. As our understanding of the environmental ramifications of these leaks continues to grow, oil and gas industry leaders are reinforcing their commitment to implementing extensive protective measures in their facilities. The question is, are they doing enough? Are utilities and heavy industry facilities inspecting their critical assets sufficiently?

To answer that question (among others), we conducted a market survey on visual inspection practices that queried 200 managers and executives within the global energy and oil & gas industries.

The growing need for inspection and monitoring

In light of the survey results, it’s important to understand why frequent visual inspection and monitoring are so critical. Utilities companies and heavy industry facilities are responsible for delivering critical infrastructure and resources, from electricity to natural gas and fertilizer, and almost always work with potentially hazardous materials. Therefore, failures and malfunctions can have catastrophic ramifications. As severe weather events become more frequent due to climate change, power utilities are also under pressure to ensure their grid is as resilient as possible and to restore power quickly after storms and other major weather occurrences.

In addition, changing societal priorities have led to increasingly strict environmental regulations, especially regarding emissions. Heavy industry is responsible for an estimated 40% of carbon emissions, and the real number may be even higher as gas emissions are notoriously underreported. In the past, the industry may not have been held accountable for its emissions, but that is no longer the case. For example, in the U.S., the recently passed Inflation Reduction Act contains extensive climate change legislation, including large fines for emissions, which companies can ill afford. The new legislation has put energy providers under pressure to both cut emissions and produces greener energy to remain compliant.

Traditional inspection is so difficult that it doesn’t get done enough

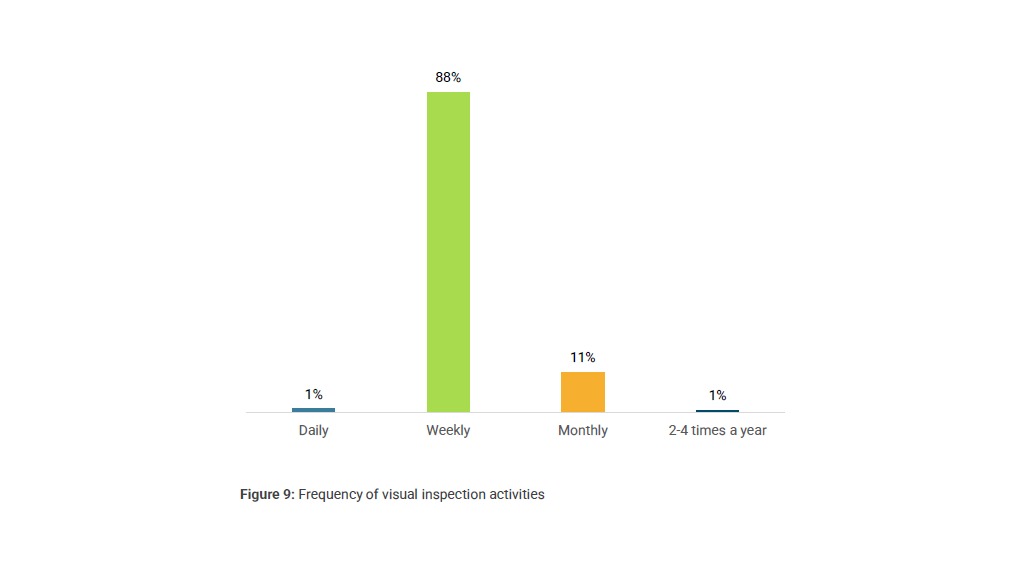

Despite the importance of visual monitoring and inspection, our survey showed that energy and oil & gas companies are falling short. Failures and malfunctions can happen at any time, which is why ideally, critical assets should be surveyed daily. However, our survey showed that only 1% of companies conduct daily inspections. Worryingly, 12% conduct inspections only monthly, or even less frequently. The significant time lags between inspections exponentially increase the likelihood of small issues becoming major problems. Beyond the safety and waste-reducing benefits of timely inspections, more frequent monitoring can also deliver huge environmental benefits, such as reducing fugitive emissions through faster detection of gas leaks.

A bigger concern is the fact that the assets inspected least, such as tanks, pipelines, powerlines, and electric poles are precisely the assets that could cause the most damage if they break down or if something goes wrong. They are also the assets that are the hardest to inspect, whether because they pose a higher risk to employees, are geographically far apart from one another, or need to be shut down to be thoroughly inspected.

Almost three-quarters (74%) of respondents said that budget and resources were the main barriers to conducting more frequent visual inspections. Yet without sufficient inspection, failures are often caught at a late stage, at which point they can lead to catastrophic loss of life, billions of dollars in fines for environmental damage, and huge losses in productivity.

Preventing the next disaster

Most companies want to become good corporate citizens, remain resilient in extreme environments, and respond quickly to mitigate disasters. However, our study shows that it simply isn’t feasible to achieve those goals using traditional manual, labor-intensive inspections, especially for hard-to-reach and critical assets.

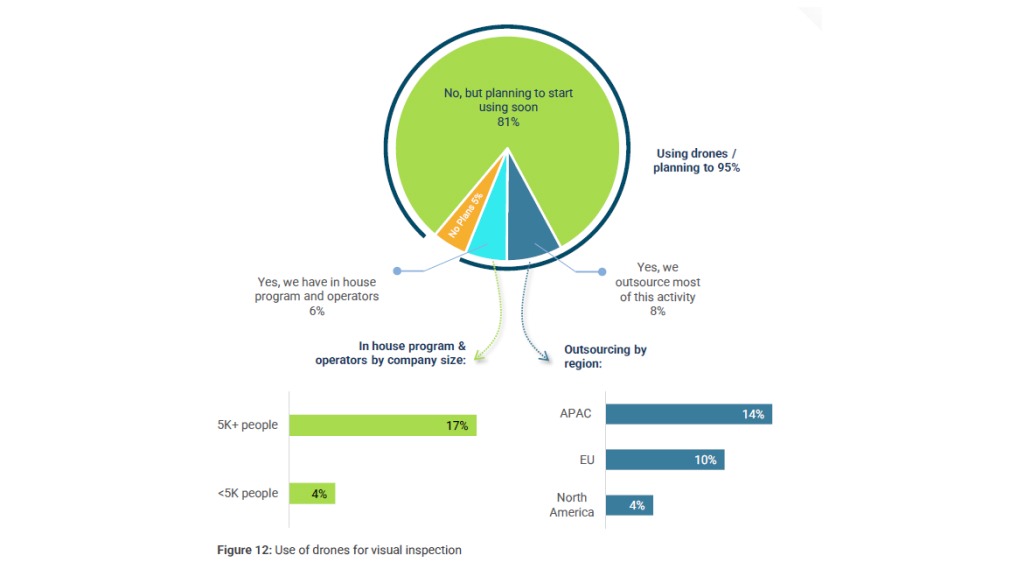

Indicating that the majority of companies recognize the value of more automated monitoring, our survey showed that while only 16% of companies are currently using drones for monitoring, a whopping 81% plan to start doing so in the near future.

When implemented as part of an end-to-end autonomous monitoring solution, drones make it easier than ever for companies to conduct inspections with the frequency needed to ensure the highest levels of safety, asset reliability and adherence to regulations. Without them, the next disaster is just a matter of time.

Get the full survey report here.