If you’re using drones once a year for PV thermal anomaly detection, that’s great. You’re running your site exactly at industry standards today for preventive maintenance. And if the benefits for deploying drones for solar panel inspections more frequently outweighed the costs, any logical site manager would be running inspections more frequently. So, do the benefits outweigh the costs?

The answer isn’t always a big, all-caps YES (and that’s coming from us).

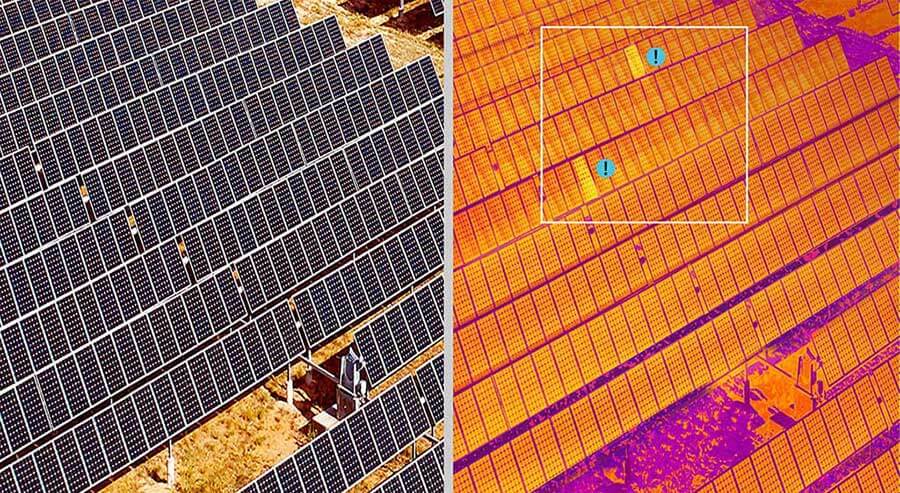

When considering adopting drones to help maintain PV farms, there is a delicate balance between productivity and OpEx costs. Optimizing productivity requires keeping a close eye on the entire solar array to spot issues like faulty trackers and panels obscured by dust or vegetation. And how clearly you can see the solar array depends on how you’re looking at it. And how often. But, reaching the right balance is a different analysis for each facility.

If you’re using drones once a year for PV thermal anomaly detection, that’s great. You’re running your site exactly at industry standards today for preventive maintenance. And if the benefits for deploying drones for solar panel inspections more frequently outweighed the costs, any logical site manager would be running inspections more frequently. So, do the benefits outweigh the costs?

The answer isn’t always a big, all-caps YES (and that’s coming from us).

When considering adopting drones to help maintain PV farms, there is a delicate balance between productivity and OpEx costs. Optimizing productivity requires keeping a close eye on the entire solar array to spot issues like faulty trackers and panels obscured by dust or vegetation. And how clearly you can see the solar array depends on how you’re looking at it. And how often. But, reaching the right balance is a different analysis for each facility.

Challenges of solar farm preventive maintenance

If your site is like most solar farms, the chances are you’re using manual inspections for day-to-day preventive maintenance. You likely have a crew regularly going around on foot or in vehicles searching for panels that need cleaning, grass or trees that need trimming and other non-electrical issues. Along with that, most facilities are also doing manual corrective maintenance inspections, such as to deal with outages issues detected by the SCADA system.

Day-to-day preventive maintenance inspections are extremely time-consuming, with most of the time spent looking for issues rather than on actual maintenance tasks. Depending on the size of your farm, site-wide ground-based preventive maintenance inspection can take months or even years. By the time you’ve finished, it’s time to start all over again. And, when it comes to outages and other electrical or mechanical issues, sending skilled technicians out long distances in the field just to locate an issue can be painfully expensive.

The labor and other costs associated with manual inspection put a serious dent in the OpEx budget, so it’s no surprise that many solar farms are inspected far less frequently than they should be.

When to consider expanding your use of drones for solar panel inspection

How do you know if automating PV inspections using drones can provide value for you? And what would be the best drone for solar site inspection?

As a rule of thumb, there are 3 key criteria to consider:

- Size

- Age

- Location

Answering yes to any of the following questions is a good indication drone-based aerial inspections would make sense for you.

- Is your solar farm particularly large?

As PV prices come down, and land prices rise, solar farms are getting bigger and bigger. Installations of 500 MW, even 1-2 GW, are already online, with more in the planning stages. Going big is simply about economies of scale; but monitoring sites that extend over many square kilometers is anything but simple. Driving around looking for broken modules and panels shaded by trees or covered in dust is slow and tedious. And even if you have a drone flying regular PV inspections, the volume of images taken over such a large area is overwhelming. Which photos do you need to look closely at? Which ones can you ignore?

Autonomous drones working with an end-to-end visual data management solution that automatically manages and analyzes the images to detect thermal and non-thermal anomalies quickly and efficiently. This approach supports frequent anomaly inspections and enables you to get actionable insights quickly. No matter how large your site, you will have comprehensive visibility.

- Is your solar farm operating for more than 10 years?

As the years go by, solar modules start to show their age, with increasing faults, hot spots and ongoing degradation in output. Identifying anomalies and their root cause early on is key to maximizing production.

Conducting PV anomaly detection using drones equipped with both thermal sensors and cameras enables you to easily find thermal anomalies that are not yet apparent to the eye. You can identify hot spots, overheated junction boxes, offline strings and other issues that commonly plague older sites, without added OpEx or additional manual inspections. You will be able to spot issues early on and ensure technicians arrive with the tools and equipment needed to quickly remedy them, reducing their impact on energy production. In addition, a cloud-based data management software enables the automated recording of anomaly data that is needed for warranty and insurance claims.

- Is your solar farm extremely remote?

When solar energy facilities are hard to access, keeping up with regular preventive maintenance is all the harder. At floating solar farms on reservoirs and canals and farms that are hundreds of miles from anywhere else it’s often too costly or logistically difficult to fly out technicians to conduct corrective maintenance, or to look for the root cause of outage issues detected by the SCADA system. Because of the complexity and cost, inspections are done far less often than they should be. Same goes for piloted drones that require a certified pilot to arrive on site, fly and then go.

To really boost inspection frequency, you’ll need a solution that allows you to operate remotely. A drone-in-a-box stays permanently on site and reports back through the cloud, providing huge value for these types of solar farms. It can be programmed and managed from anywhere and flights can be run at any frequency, without sending out personnel. Automated collection and analysis of the visual data must be part of the solution, to give stakeholders “eyes on site” no matter how far from the site they are.

Is PV inspection using drones right for everyone?

While large site size, advanced age and extreme remoteness are the prime reasons to use drones in the solar industry, other factors can also come into play. Some solar energy production sites that don’t fit those criteria still want to boost inspection frequency and the quality of the insights they get, to help them maximize productivity.

Additionally, for new solar farms, using a drone increases the chances that all faults will be detected in the handover stage, when the construction contractor is still liable, and most components are still under warranty.

Solar farms that use Percepto’s end-to-end AI-powered solution run the gamut of site types. Using our drone-in-a-box and Percepto Autonomous Inspection and Monitoring (AIM) software solution, our solar farm customers are gaining O&M benefits in 4 key areas:

- OpEx efficiency –Frequent aerial inspections allows solar farm operators to direct their team to the right place at the right time, detect early-stage faults and improve preventive maintenance.

- Scaled-up – Swapping time-consuming manual inspections for autonomous ones is key to knowing what is going on with solar farms that extend beyond the reach of human sight

- Higher yields – Thermal, comprehensive PV inspections using drones means that anomalies like an offline string, diode anomaly, or tilted tracker, are caught quickly. Timely spotting of problems empowers timely fixes, minimizing impact on energy production.

- Warranty enforcement – Anomaly data is automated recorded, providing the documentation needed for successful warranty and insurance claims.

If you’re interested in evaluating whether solar panel inspection using drones makes sense for your solar farm, we’d be happy to help.

Contact an expert in PV inspection using drones to learn more.