Harness robotics and AI to automate your site inspections

When it comes to automating your inspections, there is no better combination than autonomous robots and AI.

Drones and robots live on your site, for frequent, consistent site inspections. Daily AI-powered reports deliver insights from anomalies detected, environmental infractions, volumetric measurements, and more – so you can stay on top of your site (even if you’re off site).

Benefits of automating inspection rounds

Minimize downtime

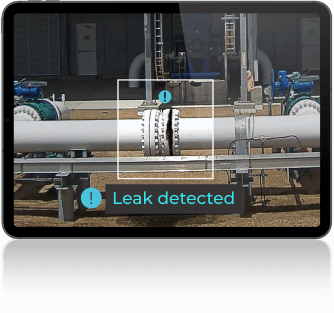

Leverage AI-powered change detection to detect failures and anomalies as soon as they happen – minimizing major failures and shutdowns.

Go digital

Automatically generate a digital system of records, with all visual data stored in one place on the cloud.

Increase efficiency

Fully autonomous inspections free up time for employees, increasing site efficiency.

Increase safety

Automate inspections and monitoring, keeping employees safely out of hazardous work environments.

Remote operations

Inspect and monitor your facilities from anywhere in the world, with autonomous drones and robots.

Minimize environmental footprint

Detect fugitive emissions, failures, leaks and other hazards protecting your employees and the environment.

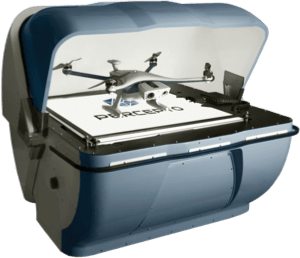

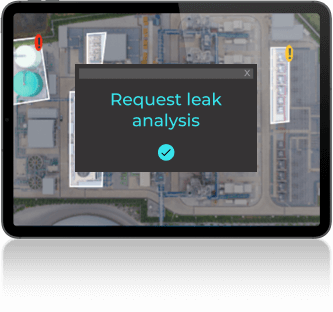

Easily automate inspections with Percepto AIM

Select an asset you want to monitor or the insight you want to receive. That’s it. In the background, Percepto AIM automates the data collection, upload and analysis to get you the information you need.

- Capture

- Upload

- Analyze

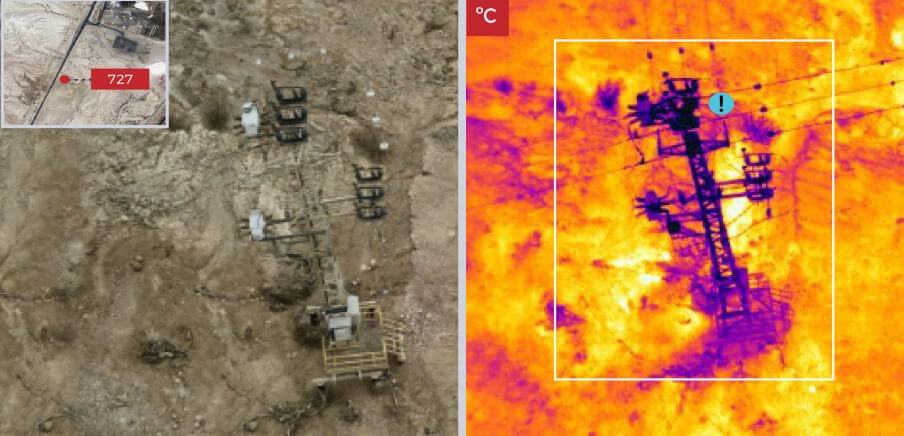

Tech highlight: change detection

Percepto AIM delivers the only end-to-end change detection solution on the market for heavy industry.

It is the key to optimizing situational awareness, effective operations and maintenance as it serves as a flawless indicator of faults or defects.

Automate inspection rounds at your facility

Electric utilities

Solar energy

Oil & gas

Mining

Industrial sites

Ports & terminals

FAQs

Automating inspection rounds

What is an automated inspection?

- An automated inspection can be used in many industries to inspect assets that are difficult to see with the naked eye.

- Automated inspections are often done by robots.

- They are usually used to detect flaws on assets that are unsafe or hard to reach.

What is an automated inspection system?

- An automated inspection system uses sensors to detect defects in assets.

- Sensors used in automated inspection systems range from cameras, drones, robots and IoT devices

- Automated inspection systems help reduce operational costs and minimize downtime while boosting safety and efficiency.

What are the advantages of automated inspections?

Automated inspections can be performed unmanned and remotely. They don’t require any special training and are less expensive than manual inspections.

What are the most common defects found during an automated inspection?

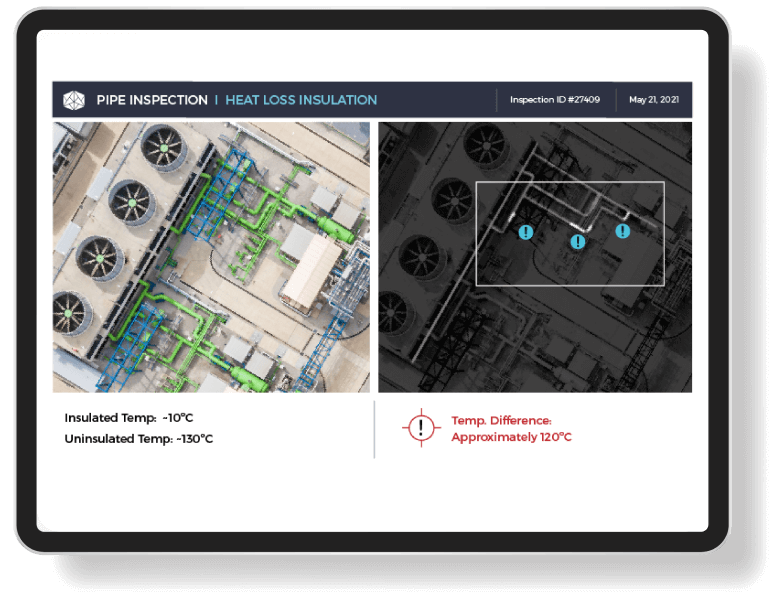

During automated inspections, some common defects include:

- Leaks

- Corrosion

- Temperature anomalies

- Physical faults, cracks and dents

- Vegetation

- Environmental infractions

How our clients fully automate inspection rounds:

International mining facility boosts productivity with fully autonomous solution

ICL Dead Sea, a leading global manufacturer of potash and other minerals, transformed their manual inspections of site assets including their electric grid, pipes and piles, into automated site inspections with one of Percepto’s drone-in-a-box solutions. Managed by Percepto AIM, the previously manual site inspections are now performed with no human involvement.