What is an on-site autonomous industrial drone (drone-in-a-box)?

An on-site autonomous industrial drone system (drone-in-a-box) is an all-in-one autonomous drone solution with two main components:

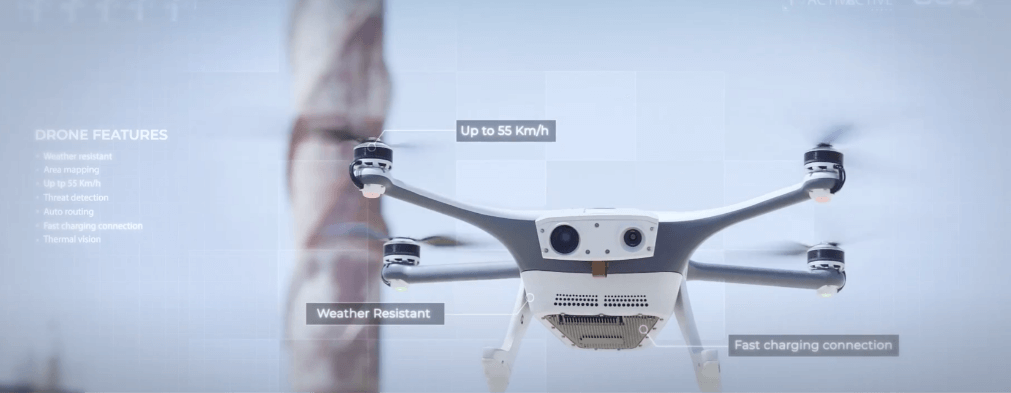

- The platform – An autonomous drone and base station (“the box”) that has been specially adapted to the unique needs to large-scale industrial sites

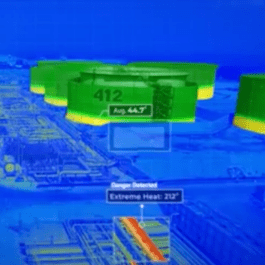

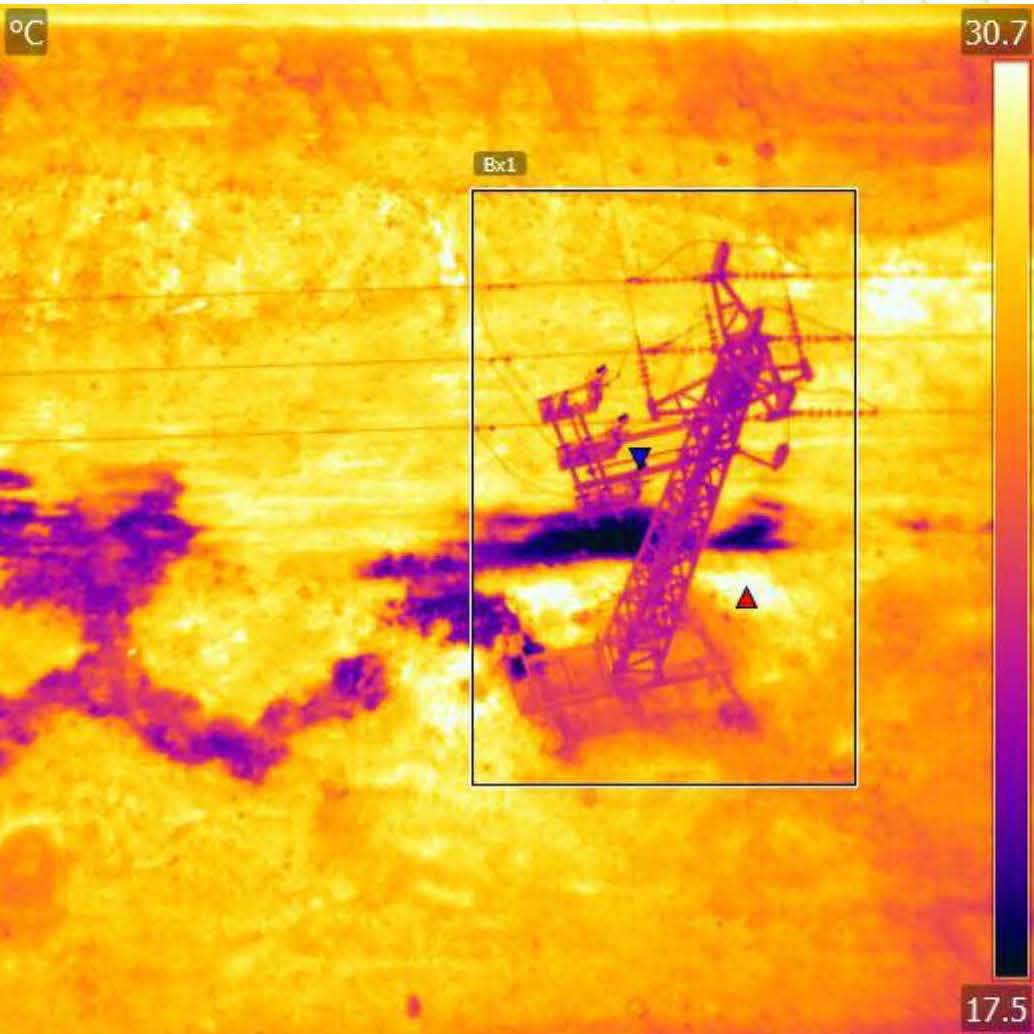

- AI-powered software that manages the drone and analyzes visual data gathered

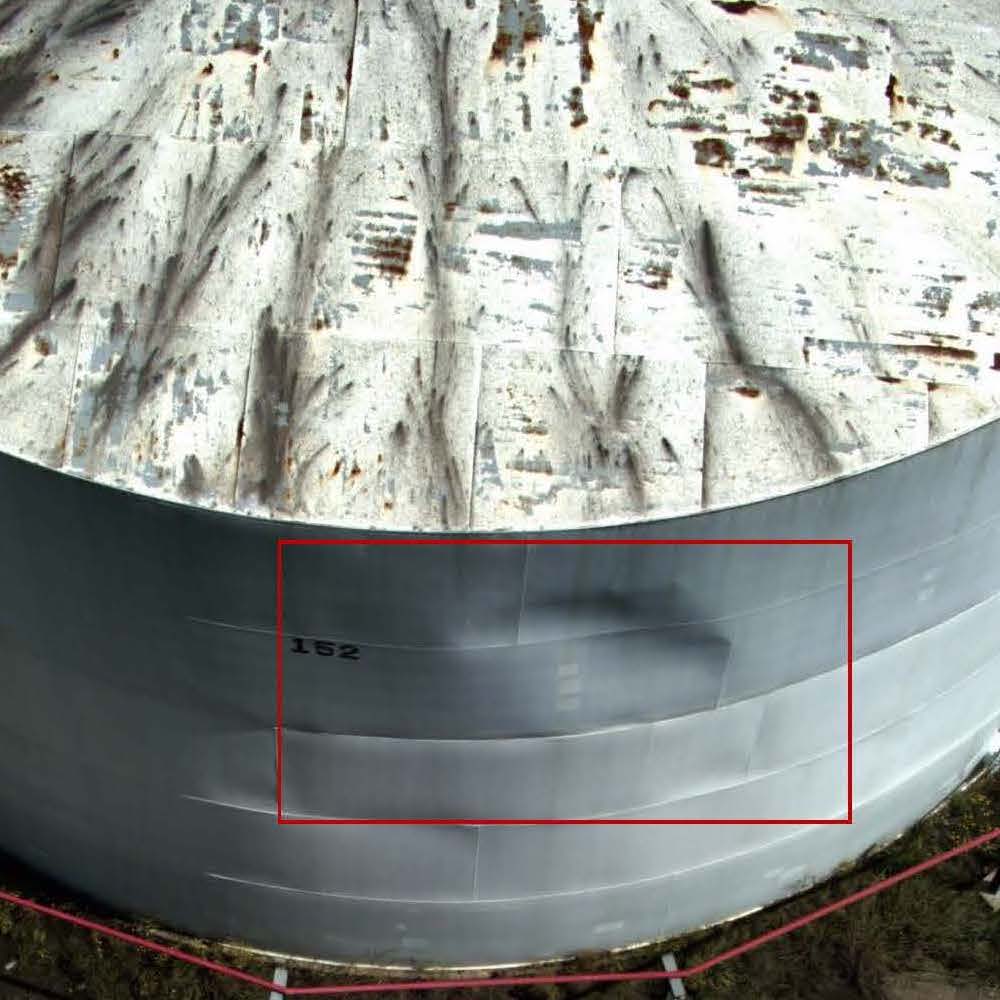

These solutions are growing in popularity because of their immediate on-site availability, convenience, and data collection capabilities. Deployed on-site, a drone-in-a-box is available 24/7/365 to enable more efficient and frequent site and equipment inspections – collecting data in a consistent and persistent way, eliminating human error, and gaining actionable AI-driven insights. These systems also enable site stakeholders to react quickly to incidents – gaining immediate situational awareness.

With a drone-in-a-box solution, all you need to do to gather high-quality visual data is program a flight path or request the information you need on any computer at any location. Without a ground-based controller or a human pilot on site, once activated, the drone gets to work – it deploys from the box autonomously, collects the right data either on-demand or pre-scheduled missions, and returns home when it’s finished. The box acts as a landing pad, recharging station, shelter, and data hub.

Industrial drone-in-a-box solutions are highly-adaptable to business needs. For example, you can launch one drone-in-a-box or combine multiple systems depending on the coverage requirements of each industrial site. During the drone mission, even if you’re off-site, you can view site conditions in real-time and also receive alerts and operational insights. If you’re not available during the mission, the system automatically generates reports based on mission findings for review at a later time.