When my co-founders and I founded Percepto back in 2014, we recognized that inspection of large industrial sites and infrastructure, such as refineries, power grids, mines, etc., was ripe for automation. By automating a process that has historically been done manually, we could prevent outages and environmental disasters, while significantly impacting heavy industrial sites’ bottom line.

Consider, a downed power grid can lead to hundreds of thousands and even millions of dollars in damages. Or the damage a gas leak can do if it goes undetected due to poor inspection. And the risk of sending an employee to inspect towers at a nuclear power plant.

We saw a clear, and massive, need and value for automating visual inspections. And we quickly understood that this is a complex, multifaceted challenge requiring an equally complex and intricate solution.

Industrial visual inspections disrupted

We’ve been working on that solution since our founding. We have spent years developing innovative technology to enhance inspections.

It was clear from the beginning that drone technology needs to play a big part in this story of automating and optimizing inspections. And in order to fully automate these processes to achieve the inspection frequency and quality needed to prevent downtime caused by power outages or oil leaks for example, we needed autonomous drones to be always available on site, these are also known as a drone-in-a-box.

So when we began, our focus as a company was on developing the most robust and intelligent drone-in-a-box on the market. And we succeeded, with our flagship drone-in-a-box Percepto Air Max (previously known as the Sparrow).

Top companies across multiple industries such as thermal energy, mining, heavy industrial, etc., finally had the tool they were so eager to have – to boost employee safety, minimize environmental footprint, and slash their downtime. And those companies, including – Koch Industries, Florida Power & Light, Verizon, Delek US, and Enel – completely disrupted their regular inspection methods, which for large enterprises is not easy.

These clients liked the results and the value they were seeing – but they still needed more. They wanted to connect all of their visual data to the same Percepto software managing the Air Max drone-in-a-box visual data. And they wanted even more AI-powered insights.

So we listened to our clients, and in November 2020 we unveiled Percepto AIM – Autonomous Inspection and Monitoring enterprise software. As the first-ever enterprise solution enabling truly autonomous visual data management, AIM was a game changer. AIM manages a fleet of robots residing on site collecting visual data, and automatically generates AI-powered insights relevant for various stakeholders (i.e. maintenance, compliance, and security officers). It remains the only solution on the market that solves the most challenging inspection-related workflows – data collection, data management and data analysis, all in one platform. We couldn’t be more proud and excited seeing it selected by TIME as one of 2021’s most groundbreaking solutions, who recognized AIM’s ability to minimize risk, pollution and even prevent large-scale environmental disasters.

In heavy industry, automation and drone use is now seen as the standard in inspection practices. Our 2021 solution, combining powerful autonomous robots with AI-powered visual data management is the nuanced and advanced solution industrial sites today can rely on to reduce risk, costs and environmental impact.

Aiming higher, and lighter

Since we laid the groundwork for visual inspection automation with Percepto AIM and Percepto Air Max, we’ve been striving to tackle a few more of our client and market challenges – namely the fact that “one size doesn’t fit all”.

Different industries and companies have different inspection needs. They may need more accuracy, like the mining industry, which relies on highly accurate volumetric measurements to monitor productivity and plan shipments. Or special sensors, like the oil & gas industry, whose main concern is preventing leaks and detecting specific gasses as soon as they appear.

Some companies have different inspection needs internally for their different facilities. Like a power company that needs a heavy-duty, ruggedized drone solution at their substations and nuclear energy facilities, but a lighter and more mobile drone solution to monitor their entire power grid.

And sometimes facilities don’t need a drone. They may need a ground robot, like Spot®, indoors. Or they may have fixed cameras already looking at the right assets, but are missing the visual data management, analysis and reporting capabilities.

The list goes on. And we compiled that list, packaged it up and delivered it in our latest solution upgrade.

We developed AIM 2022 and a new drone-in-a-box. We created a mobile app, and offer fully automated integrations with DJI drones and fixed cameras. And together, these solutions offer companies the ability to automate their visual inspections in whatever way works best for them.

What’s in AIM 2022

Building on the success of AIM 2021, AIM 2022 delivers yet another game changer for industrial sites – Insight Manager. Insight Manager packages the most advanced industry-specific analytics in a way that is accessible to any user. Our clients grappled with challenges of siloed data, and the need to rely on 3rd party analytics or experts to get the insights they need.

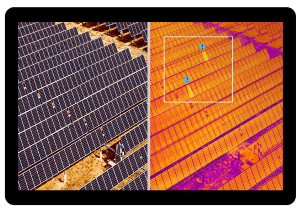

And Insight Manager eliminates those challenges. At the click of a button, any user selects the insight they need, and AIM 2022 does the rest – dispatching the correct robot for inspection, and utilizing AIM 2022’s next gen change detection framework to automatically detect anomalies, or generate volumetric measurements.

Faults are detected as soon as they happen, preventing them from turning into larger failures causing downtime, outages, or environmental catastrophe. Positive changes are also detected, and our clients leverage AIM 2022 to monitor construction projects, with each component constructed detected, counted and tracked on a map.

AIM 2022 also packs in significant user experience upgrades, addressing our client needs for greater mobility and collaboration. This includes our new mobile application, user interface upgrades, and faster and easier insight sharing. For our clients, these upgrades effectively solve organizational challenges, by removing information bottlenecks and empowering any user to automate visual inspections.

What’s in the new box

The “smallest” addition to our solution this year is Percepto Air Mobile. This smaller, lighter and as the name suggests – mobile – drone-in-a-box directly addresses client needs for a solution that can be easily deployed at multiple locations, such as a pipeline or power grid. The new solution is also weatherproof and highly ruggedized, like it’s big brother the Air Max.

In contrast to the lighter Air Mobile, the new Air Max upgrades make it the heavy-weight champion of visual inspections. With the most accurate, high-resolution sensors including new cameras and optical gas imaging (OGI), the Air Max is the only drone-in-a-box on the market capable of meeting our oil & gas client needs for effectively detecting and preventing gas leaks and unwanted emissions.

With our 2022 solution, we also introduced integrations with DJI and fixed cameras. Adding these sensors to our portfolio enables any industrial site to integrate their existing visual inspection tools into an end-to-end visual data management platform. Giving them the highest quality analytics on the market for industrial inspection, this integration delivers a critical solution for large enterprises for which “one size does not fit all.”

One solution for every industrial site

With AIM 2022, the value proposition for automating visual inspections is greater than ever. The most advanced AI in our most user friendly platform ever guarantees reduced downtime, costs, risk and environmental footprint.

And our solution is now so versatile, that any company in any industry can begin automating visual inspections at their facilities where they need it most. For some, that may look like a software only solution to upload data from existing on-site sensors into Percepto AIM. For others, it may be using DJI drones with automatic visual data collection and management. And for the most complex industrial environments, there’s the flagship Percepto Air Max.

Autonomous visual inspections are becoming the standard, best practice at heavy industrial sites. And with a flexible, adaptable solution, we’re aiming to automate inspections at every green energy facility, power grid, pipeline, and more.

With AIM 2022, we believe we have paved the way for every industry and every industrial site to use drones and robots at their worksite for visual inspection. Since we have put in countless hours to develop and fine-tune our solution, we were determined to make it accessible to all. Because our vision for all facilities and infrastructure to automate visual inspections means a brighter, safer future for everyone.